The positive material identification test – PMI test – serves as a proof of the alloying constituents present in the material, confirming the melting analysis of the material contained in the 3.1 certificate.

There are two different test procedures common for thermowells:

1. PMI test: X-ray fluorescence analysis (XRF)

X-ray fluorescence analysis uses X-rays to stimulate the atoms of the thermowell material to produce natural radiation, without damaging the surface of the metal. The wavelength and intensity of the emitted radiation is, in turn, a measure of the alloy’s constituent elements and their concentration.

2. PMI test: Spectrographic analysis (OES)

With spectrographic analysis (“Optical Emission Spectroscopy”), an arc is generated between the thermowell surface and a tungsten electrode in the test instrument, and the spectrum of this arc enables the alloy’s elements to be identified – both qualitatively and quantitatively.

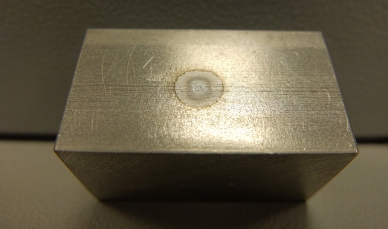

For the OES, it does leave a characteristic burn mark of approx. 5 mm diameter on the workpiece.