Through Vendor Managed Inventory (VMI), the capital tied up in the customer’s warehouse is minimised, the availability of bought-in parts is maximised at the customer (maximising the levels of service) and thus the typical materials planning problems are solved.

Typical materials planning problems

With the supplier, precise information on the actual demand of his customer is not available. This demand is also subject, to a degree, to considerable fluctuations for a variety of reasons. The customer is stuck with the dilemma between tying up a lot of capital in stock purchases or having too few bought-in parts available. The latter means that a rapid response to customer requirements in the overall supply chain is not possible.

Solution method – Vendor Managed Inventory (VMI)

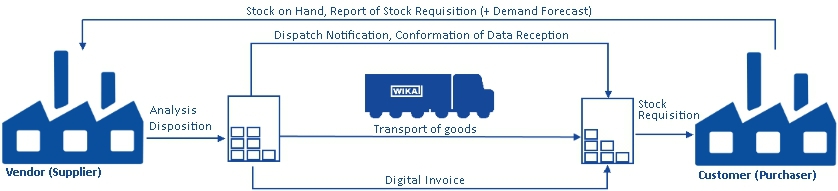

An agreement is struck between the customer and the supplier. With this, the customer grants the supplier insight into his needs and inventory. The customer transfers his materials planning to the supplier completely. Thus, the contents of the agreement essentially consist of three key points: stock information, replenishment lead time and delivery.

Implementation of Vendor Managed Inventory (VMI)

Customer and supplier establish an automated process between themselves. In this way, the supplier (on a weekly basis, for example) – via automated data transfer – obtains the inventory and orders without the customer having to intervene in any way. The supplier generates the order in his own ERP system and on that the planning and production are based. Likewise, the supplier assumes the checking of the order confirmation and also the tracking of the delivery. The customer only needs to initiate the data transfer and can easily monitor the delivery performance.

Practical experience at WIKA

Due to the implementation effort, VMI is just the right thing for large required quantities. Our experience shows that VMI can significantly contribute to improving the service level and reliably balancing fluctuations in demand, in particular. As a rule, stable service levels in the range of 99 % can be realised in the long term by VMI agreements.

Conclusion

Between the customer and the supplier there must be a clear relationship of trust, since Vendor Managed Inventory (VMI) brings with it both advantages and disadvantages. While the customer incurs a high dependancy on the supplier, he clearly has a lower burden of work and responsibility. In return, the supplier gains a strong customer tie-in, though he does take on a very high responsibility with this. Both partners achieve a clear win-win situation, with the disadvantages for both sides more than offset.

Note

Further information on Vendor Managed Inventory (VMI) at WIKA can be found on our website. In general, we also offer customer-controlled materials planning, such as DELFOR (Delivery Forecast). Please use the contact form on our website to get in touch with us about this and other e-business topics.