Validation of calibration software - as required by ISO 17025, for example - is a topic that people don't like to talk about. Often there is uncertainty about the following: Which software actually must be validated? If so, who should look after it? Which requirements …

Calibration

Traceability

| Matthias Bundschuh | Know-howMeasuring instruments for pressure and temperature are used in almost all areas of industrial manufacturing. As a result of continuous mechanical, chemical and thermal loading, these instruments age and can therefore not guarantee the correctness of the measured values …

“Oxygen, oil and grease free” in calibration technology

| Jens Rollmann | Pressure, ProductsOxygen, the gas essential for life, is far more complex in industrial applications than our daily inhalation and exhalation suggests. Industry – especially in the chemical, pharmaceutical or medical engineering fields – is, time and again, finding itself confronted …

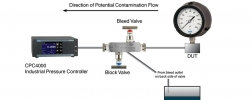

Calibration / contamination control with a block and bleed valve

| Larry Mock | Know-howA block and bleed valve can be used to prevent flow of contamination from a device under test (DUT) to a pressure controlling calibrator. This procedure includes “exercising” and purging the DUT and the actual calibration. Your procedure may be different but the …

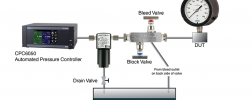

Calibration / contamination control with a block and bleed valve and coalescing filter

| Larry Mock | Know-howWhen calibrating or testing a gauge or transducer with a pneumatic pressure controller it is important to protect the controller from any liquid contaminants that may be present in the device under test (DUT). A block and bleed valve (BBV) in-line with a coalescing …