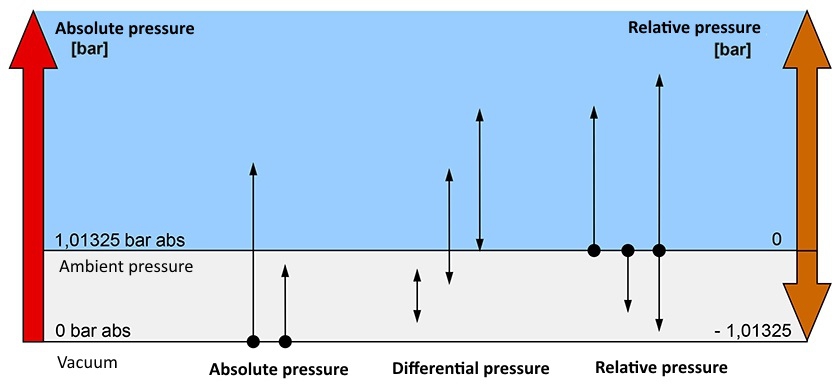

Within the selection criteria for pressure gauges, type of pressure takes top priority. The measurement of gauge pressure, in fact, reliably fulfils the purpose with the majority of processes. However, for numerous applications in industry, pressure gauges for absolute or differential pressure come into consideration. This article presents the differences between the three types of pressure:

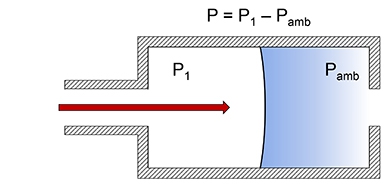

Gauge pressure

With gauge pressure, the pressure gauge measures the difference to atmospheric pressure, also referred to as ambient pressure. This pressure varies depending on the weather and height above sea level. At sea level it averages 1013.25 mbar. Since virtually all points in a production plant are generally exposed to the same air pressure, gauge pressure measurement is normally sufficient for industrial applications.

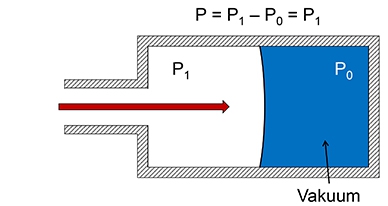

Absolute pressure

Absolute pressure is always in reference to the zero pressure which is obtained with a full vacuum. Pressure gauges for this type of pressure should therefore always be selected when the smallest change in atmospheric pressure could affect the process. Typical applications for absolute pressure measurement are the determination of the vapour pressure for liquids, the monitoring of condensation pressures and also in distillation. Further application examples are vacuum pumps and equipment for the food industry.

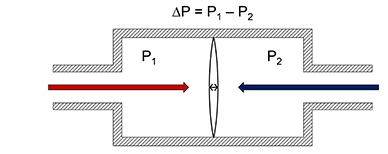

Differential pressure

With differential pressure, we are talking about a type of pressure which – as the name suggests – specifies the difference between two pressures. Differential pressure gauges therefore have two process connections. They are used, for example, in the monitoring of filter and pump systems. With this type of pressure it is also possible to determine the fill level in a closed tank – This is derived from the difference between the total pressure (liquid column + gaseous phase) and the pressure of the gaseous phase.

Note

You can find further information on pressure gauges on the WIKA website.