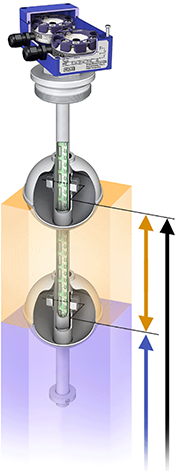

One speaks of an interface measurement when two different liquids in a tank or container are measured independently of one another. Such an interface measurement is always useful when the liquids are not miscible with each other, as is the case with oil and water, for example.

Example of an interface measurement: Oil at the top and water at the bottom

In practice, the float-based level measurement technology is often used for interface measurement. Two floats are adjusted to the respective densities of the two liquids. This results in a simple but very reliable interface measurement.

A key advantage of this method of measurement is that no time-consuming settings have to be made on the level sensor. In addition, the float-based level measurement is easy to install and largely maintenance-free.

Interface measurement with two floats and two head transmitters

Known for its robustness: the reed chain

In applications with high shock and vibration requirements, the reed chain has made a name for itself as a proven level measurement technology. The magnet system inside the float actuates reed contacts, which are located inside the guide tube on a resistance measuring chain. The series connection of the reed contacts and resistors generates a variable resistance value, which changes proportionally to the level. A head-mounted transmitter then converts the measured resistance value into a 4 … 20mA/HART® output signal. Depending on the choice of head transmitter, other output signals such as PROFIBUS© or FOUNDATION™ Fieldbus are also possible.

This default configuration can be modified very easily to allow monitoring of the levels of two liquids at the same time. In interface applications, a second head transmitter can be used to evaluate the position of a second float. This means that a measuring instrument with a reed chain can monitor two floats via two independent 4 … 20mA/HART® signal outputs. Thus, monitoring interface applications with two floats is no problem for the reed level transmitter.

Note

Further information on the topic of level measurement with floats can be found on the WIKA website. If you have any questions, your contact will gladly help you.

Also read our posts

Float switch: What is it and how does it actually work?

Reed level sensor: Defining the measuring range flexibly

What do dead bands mean with a float switch?