In the past, monitoring the filling level in liquid gas tanks using differential pressure has always been a challenge. This is because the manufacturers of tank equipment had to construct their own measuring systems in order to record the liquid level and the operating pressure of the respective gases. With the innovative differential pressure gauges from WIKA’s Cryo Gauge series, they have a compact all-in-one solution that saves time and money.

High pressures and very low differential pressure

In industry, but also in medical facilities, gases such as oxygen, nitrogen, argon, carbon dioxide and nitrous oxide are elementary operating materials. They are stored in liquified form in tanks. Differential pressure gauges are an ideal solution for level monitoring in closed vessels. However, most of these instruments have their limits when it comes to the level in liquid gas tanks. On the one hand, they have to be robust enough to handle high pressures and on the other hand sensitive enough to indicate a very low differential pressure.

In addition, differential pressure gauges are usually limited to a pressure range and can therefore only be calibrated for a specific gas over the entire span. The consequence of this is shown here using the example of nitrogen, oxygen and argon: N2 is lighter than O2, which in turn is lighter than Ar. If all three gases were in tanks of the same size and as full as each other, the measuring instrument’s scale would only show the N2 filling as 100 percent, while in the case of O2 and Ar only 70 and 57 percent. Consequently, a tank manufacturer would have to install a different differential pressure gauge for each gas. Or they would need to use a pressure gauge with three gas scales, of which only the argon scale would cover the full measuring range.

Indicating more than just the filling level of liquid gas tanks

In the case of liquid gas tanks, it is not enough just to know the filling level. The vessels also require a pressure gauge to indicate operating pressure and a compensating valve to set the point to zero during routine testing. Before the WIKA Cryo Gauge appeared on the market, manufacturers of tank equipment had to procure differential and working pressure gauges, valves, fittings and piping. From this they would build a measuring system with several connections (= potential leakage points) and then test it for leak tightness. In the case of oxygen, the necessary purification also came into play.

Innovative design

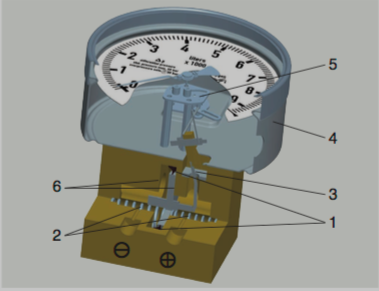

Schematic representation of the Cryo Gauge assembly

The design of this engineered solution is simple yet innovative: Two media chambers, ⊕ and ⊖, measure the pressure of the gases (P1) and liquids (P2). An elastic diaphragm (1) divides the two chambers. The differential pressure (P1 minus P2) leads to a deflection of the diaphragm against the measuring range spring (2). This movement is proportional to the differential pressure. It acts on a low-friction lever mechanism (3) in the indicator case (4) in order to transmit the pressure information to the movement (5). Metal bolsters (6) on both sides of the diaphragm protect the instruments from overload and pressure peaks. The measuring cells are made of a copper alloy (models 712.15.100/160) or 316 stainless steel (models 732.15.100/160). The other wetted parts and most of the non-wetted parts are also made of corrosion-resistant stainless steel.

Cryo Gauges offer numerous advantages

Monitoring the fill level in liquid gas tanks with WIKA Cryo Gauges has a number of advantages:

- Robust design: The measuring instruments are insensitive to pressure peaks. They are overpressure safe up to 50 bar (725 psi) on either side. A Cryo Gauge will therefore not suffer any damage, even if the pressure lines are crossed or the valves are opened in the wrong sequence. The pressure gauges also have a non-fogging window.

- Wide pressure range: Despite their robustness, Cryo Gauges are sensitive enough to measure very low pressures, down to 16 inches of water column (inH2O) . The measuring range is between 16 and 1,600 inH2O (which corresponds to 40 mbar and 4,000 mbar). Most differential pressure gauges on the market have much tighter limits.

- Easy span adjustment: Cryo Gauges enable on-site span adjustments without first having to dismantle the entire assembly. To do this, simply remove the rubber sealing cap, insert the Allen key (supplied) into the access port, turn it and reinsert the plug. No zero point adjustments are required for minor adjustments. This is particularly useful in applications where the full scale indicates a full tank, such as bulk storage of liquid carbon dioxide. As an example: The scale of a six-ton tank indicates 12,000 pounds of liquid CO2. Once the tank is full, the user expects the gauge to show that amount. Despite a very careful tank calculation, many variables can affect the behaviour of the gas, resulting in a reading indicative of a tank that is not full. With Cryo Gauges, after filling the tank, the user can make a final span adjustment to match the full tank.

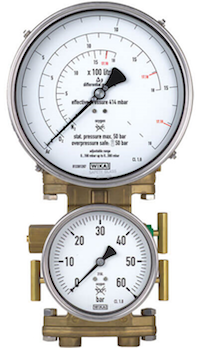

Model 712.15.160 Cryo Gauge with optional operating pressure indicator

- Modular design: The unique modular design of the Cryo Gauges enables the assembly of individual measuring systems with different functions. Starting from the level unit, users can later add a manifold block with a pressure gauge or even a sensor for the operating pressure, on-site. Further options are an integrated 4 … 20 mA output signal for the level, a separate operating pressure transmitter, integrated level switches, operating pressure switches and a large number of mounting brackets.

- Easy commissioning: The Cryo Gauge measuring systems can be commissioned without any problems, almost “plug-and-play”. Independent of the integrated functions, the compact assembly only has two connection points: one for the liquid phase and one for the gas phase.

- O2-cleaned and leak-tested: Equipment for oxygen applications must be specially cleaned to remove contaminants such as hydrocarbons (oils), particles and moisture. WIKA supplies Cryo Gauges already O2-cleaned for such applications. This saves the manufacturers of tank equipment one work process. This also applies to the leak testing. WIKA subjects each assembly to a thorough helium test to ensure there are no leaks.

- Equipped for telemetry: Liquid gas suppliers are increasingly taking on the task of monitoring their customers’ consumption. Such remote services improve delivery security and efficiency. The level indicator of the Cryo Gauges can be equipped with an integrated pressure transmitter that is connected to the telemetry unit. This eliminates the need for a separate pressure source for the transmission module, which could lead to different measured values.

Note

You can find further technical details on the Cryo Gauge models 7×2.15.100 and 7×2.15.160 on the WIKA website. There you can also find information on other measurement solutions for cryogenic tanks. If you have any questions, your contact will gladly help you.

Also read our posts

Diaphragm seal system detects level in PTA reactors

Electronic differential pressure measurement for level monitoring