I was a freshly graduated mechanical engineer when I started my career in the maintenance department of a petrochemical plant. One of the many jobs that we needed to attend to was checking the status of the pressure transmitters that were installed on our production …

Pressure sensor

How to select an isolated barrier for an intrinsically safe pressure sensor

Stefan Heusel | Know-howIn Europe plants or machines used in hazardous areas must comply with the ATEX directive 94/9/EC. Therefore, the pressure sensors or other measuring instruments approved according to ATEX must be used only in conjunction with ATEX approved isolated barriers if they use …

Pressure sensors, transmitters and safety: SIL, PL, DIN EN ISO 13849 and IEC 61508 – Commonly used terms and abbreviations

Stefan Heusel | Know-howWhen using pressure sensors and pressure transmitters, our customers often ask for explanations of frequently used terms and abbreviations in connection with "SIL applications". SIL – which means Safety Integrity Level, and PL, which means Performance Level, are …

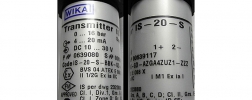

Ex pressure sensors and transmitters for ATEX Zone 0, Zone 1 or Zone 2 – markings of pressure instruments for use in a hazardous area

Stefan Heusel | Know-howThe field of application or the suitability of a pressure sensor for a hazardous area is designated by the marking on the device. As a matter of principle, intrinsically safe pressure sensors marked Ex ia can be used in zone 0 (the "most dangerous" area), whereby …

Fields of application for pressure sensors 3 – Absolute pressure sensors: why is it necessary to use absolute pressure sensors or pressure transmitters

Stefan Heusel | PressureElectronic pressure sensors usually measure the change in pressure through the deformation of a diaphragm. If this diaphragm is exposed to the process pressure on one side and "vented" on the other side (and thus exposed to the ambient pressure), the deformation is …