Are pressure gauges suitable for pharmaceutical processes? Yes, if they are available in a version with flush diaphragm element. There are two advantages for a mechanical pressure measurement with this type of instrument: Diaphragm pressure gauges measure “dry” and thus reduce the risk of contamination. In addition, they offer a reliable measurement, even in critical situations, due to their extremely robust diaphragm element and the high overload safety.

In numerous pharmaceutical processes, diaphragm seal systems are used to control the process pressure, also in combination with a pressure gauge. A diaphragm seal separates the measuring instrument from the process and thus protects it against influences. Its sensitive diaphragm for the transmission of pressure through liquid is relatively thin, due to the accuracy of measurement. Compared to the diaphragm as the pressure sensing element of a diaphragm pressure gauge, it is therefore more susceptible, both to unpredictable process conditions (pressure peaks, overload) and to mechanical influences. If the diaphragm is damaged, system fill fluid can enter the process.

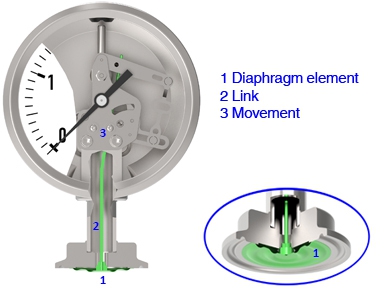

The mechanism of a PG43SA pressure gauge with flush diaphragm element

No contamination

Pressure gauges with a flush diaphragm element eliminate such contamination since they operate without liquid. Their robust diaphragm element transmits the pressure, via a link, directly to the movement. It is two to five times as thick as a conventional diaphragm seal diaphragm. The diaphragm element is therefore effectively protected against unexpected physical effects. In addition, it can absorb a high overload ‒ with WIKA instruments this is up to five times the nominal pressure.

Furthermore, pressure gauges for pharmaceutical processes must meet the stringent requirements for sanitary applications in every respect. This has been implemented by WIKA in its PG43SA series. For their instruments, a diaphragm element of only 35 mm in diameter was developed. Due to its special wave contour and the thickness of its material, the diaphragm has a measuring quality comparable to the diaphragm element of a typical process instrument – though this would be more than twice the size for a comparable pressure range.

Easily cleanable

All instruments of the PG43SA series comply with the guidelines of hygienic design, the 3-A Sanitary Standard and are certified to EHEDG. They are suitable for CIP/SIP processes and are optionally completely autoclavable.

Two of the models (PG43SA-S and PG43SA-D) are pressure gauges with a radial process connection. For the model PG43SA-C, however, the process connection is integrated into the case. This patent-pending design enables space-saving and therefore flexible installation.

Integrated safety system

The model PG43SA-D has been tuned to suit particularly critical processes. The pressure gauge has a patent-pending integrated safety system. It includes a second protective barrier and diaphragm element monitoring. Should an unexpected diaphragm rupture occur, the process and measuring instrument remain securely separated. The medium cannot escape into the environment and likewise, nothing contaminating can find its way into the process. Any instance of damage becomes known immediately: The diaphragm element monitoring reports it directly via a red indicator on the dial.

Designed as pressure gauges for pharmaceutical processes (f. l. t. r.): Model PG43SA-S (standard), model PG43SA-C (process connection in case) and model PG43SA-D (with additional safety system).

Note

For detailed information about the three diaphragm pressure gauges PG43SA-S, PG43SA-D and PG43SA-C, please visit the WIKA website. A concise overview is provided by the flyer for this instrument family.

For further information please watch the following video about the diaphragm pressure gauges of the PG43SA series: