One of the world’s largest big-box retailers has installed a network of WIKA IIoT Solutions Leap Sensors® in its climate-controlled warehouse for the wireless monitoring of humidity, temperature, differential pressure, and other critical conditions.

In climate-regulated warehouses, “good enough” monitoring is not an option. From small storage rooms to large distribution centers and specialized cold rooms, maintaining precise conditions is essential for product quality, regulatory compliance, and safety.

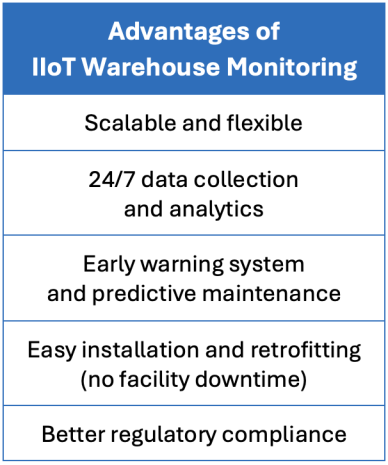

Modern wireless temperature and environmental monitoring systems deliver scalable, real-time insights that reduce risk and boost operational efficiency. Benefits include:

- Scalable monitoring for facilities of any size

- Intelligent sensor networks providing actionable data

- Real-time alerts to prevent product loss and compliance breaches

- Automation and integration to streamline device detection, reduce manual labor, and accelerate product release

Even better? Finding a provider that can help with customized solutions for seamless retrofitting so that modernizing doesn’t require downtime.

The Cold Storage Monitoring Challenge

A global retailer needed an automated remote temperature and environmental monitoring solution for one of its U.S. cold storage warehouses. The facility operates nonstop, which meant shutting down even a single sector for a few hours was not an option. Installing a traditional wired monitoring systems would have required costly downtime, even if completed sector by sector.

Advantages of IIoT warehouse monitoring

Requirements for Wireless Warehouse Monitoring

To address the challenge, the retailer partnered with an engineering and technology design firm specializing in supermarkets and refrigerated systems. Together, they defined system requirements that called for more than 150 wireless monitoring nodes capable of frequent, reliable data collection and transmission. The solution needed to track a range of critical measurands essential for regulated environments:

- Dew point and humidity

- Temperature: in both refrigerator and freezer ranges

- Pressure: up to 400 psi (28 bar)

- Differential pressure: in the low <4″ WC (0.4 mbar) range

- Electrical current

- Flow meter pulsation

Each node would integrate with gateways for seamless data transfer. Equally important, the monitoring system needed to support fast deployment, with installation complete in hours rather than days – all while the warehouse remained fully operational.

Wireless Environmental Monitoring with WIKA IIoT Solutions

In its search for an Industrial IOT solution, the design firm identified WIKA IIoT Solutions, a wholly owned subsidiary of the WIKA Group. With proven expertise in wireless sensing technology and remote environmental monitoring, WIKA IIoT Solutions was uniquely positioned to deliver a scalable, high-precision system that met the retailer’s strict compliance, reliability, and zero-downtime requirements.

The Solution: Wireless Leap Sensors® for Cold Storage

(from left) Industrial-grade wireless temperature and humidity sensor, wireless sensor gateway (click to enlarge)

WIKA IIoT Solutions customized and shipped roughly 170 Leap Sensors® wireless transceiver nodes along with 10 industrial-grade gateways. About 75% of the nodes were configured for dew point and humidity monitoring, while many included multiple sensors to also track temperature, pressure, differential pressure, electrical current, and flow pulsation.

Each node was set to transmit readings at user-defined intervals – typically every 10 minutes, though rates can be shortened or extended as needed. For this freezer warehouse, data was sent to a SQL database and accessed through a custom-built user interface, with the option to use WIKA IIoT Solutions’ LeapSensorManager® software.

Thanks to the wireless design, this smart warehouse system was integrated and commissioned quickly with remote after-sales support, all while the warehouse continued running without disruption.

WIKA and WIKA IIoT Solutions: Trusted Partners for Wireless IIoT Monitoring

By leveraging WIKA IIoT Solutions’ Leap Sensors® and wireless monitoring expertise, the global retailer achieved a scalable, cost-effective, and high-precision IIoT solution that ensures compliance, maintains product integrity, and minimized operational disruption.

Today, WIKA and WIKA IIoT Solutions continue to help industrial and warehouse operators implement remote temperature monitoring and environmental monitoring systems that enable predictive maintenance and reliable inventory protection. Discover how WIKA USA and WIKA IIoT Solutions can customize wireless monitoring solutions to meet the unique needs of your warehouse or manufacturing facility.

For more information, contact WIKA USA.