In applications with vibration and pulsation, either a liquid-filled case or dampened movement industrial instrumentation will minimize pointer oscillation. The better choice depends on the application and, to a certain extent, a user’s risk tolerance for leaks.

Pointer flutter is a common problem among industrial pressure gauges and dial thermometers found in applications with mechanical vibration and pulsation. As the instrument wobbles and shakes, so do all the internal parts, including the pointer. The results? Mechanical vibrations increase the wear and tear of the internal parts, and technicians cannot get a precise reading on the pressure or temperature.

Best Practice for Tackling Pointer Flutter: Liquid Filling

There are two ways to prevent pointer oscillation. One is to use a liquid case filling. In industrial pressure gauge, the liquid fill – usually glycerin or silicone oil – also:

- Cools the vibrating metal parts

- Lubricates the mechanism, thereby reducing wear and tear

The above benefits greatly increase the service life of the instrument and reduce downtime due to pressure gauge failure. In the long run, liquid-filled gauges are smart investments that ultimately save users money and time.

Customers may be concerned about potential leaks of liquid-filled cases. Some of our competitors’ gauges and thermometers do tend to lose their case fill over time, but not WIKA instruments. We use superior materials. For example, the Pocan® thermoplastic cases of our XSEL® process gauge line will not absorb moisture, an important consideration because moisture could lead to cracks. In addition, WIKA’s liquid-filled gauges undergo several leak tests to make sure they are 100% leak tight before being filled, either at the factory or in the field. Unless they are mishandled or abused, our liquid-filled gauges and thermometers will not leak.

When to Use Dampened Movement Industrial Instrumentation

However, some industries cannot tolerate even the smallest risk of leaks. These include pharmaceutical companies, paint manufacturers, and food and beverage plants – even if the case filling is FDA approved. In certain environments, such as barges, any type of spill is considered a safety hazard that must be documented and reported to the Coast Guard.

When mechanical vibration prevents these industries from using a traditional dry gauge or dry thermometer, a good option is dampened movement industrial instrumentation, especially when the gauge is coupled with one or more protective devices, such as a restrictor, snubber, and/or needle valve.

The Principle Behind Dampened Movement

Pressure gauge with dampened movement

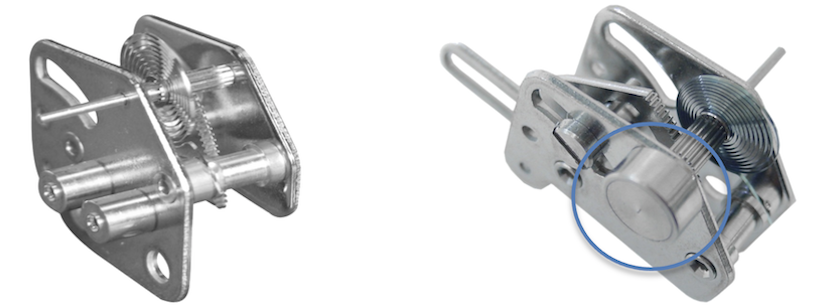

In a WIKA pressure gauge, its Swiss movement is the most critical component for converting the pressure input into a precise indicator. The movement comprises a link connected to a segment gear that moves the pinion gear wrapped around the pointer shaft. In a standard movement instrument, vibration and pulsation are transferred to all moving parts, causing the pointer to flutter and making a precise reading nearly impossible.

(left) standard movement, (right) dampened movement

With WIKA’s specially engineered dampened movement technology, the entire instrument still shakes – all except for the pointer shaft. This fully sealed capsule (circled in blue) is filled with a highly viscous silicone grease. The capsule has a brass inner drum that rotates inside the capsule housing on a thin film of that silicone grease, which isolates unwanted vibrations from the pointer shaft, thereby eliminating pointer flutter. In addition, the fully encapsulated disc keeps the dampening media in and the dirt out. Other gauge manufacturers use a sleeve design that allows the dampening media to dry out over time and to migrate under higher temperatures.

Bimetal thermometer with dampened movement

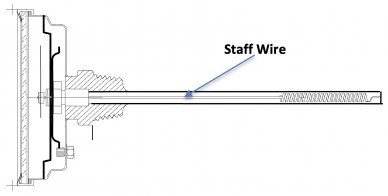

Bimetal thermometer with dampened movement

WIKA is the maker of the world’s first dampened movement bimetal thermometer. The dampening principle and technology are similar to those of a pressure gauge. But instead of a pointer shaft, a staff wire connects the bimetal helix with the pointer. This staff wire leads through a bearing that is filled with NyoGel®, an inert synthetic hydrocarbon grease with very heavy viscosity. This grease greatly minimizes pointer flutter caused by vibration, even in extreme temperatures.

This silicone-free instrument is available in temperature ranges not possible with case fill. Furthermore, its completely welded construction and hermetically sealed case eliminates the possibility of cross-contamination.

Pros and Cons of Dampened Movement

WIKA’s Dampened Movement is an excellent option for stifling vibration and pulsation in applications where liquid filling is not permissible. Our pressure gauges with this technology offer the same temperature range as standard dry gauges, from −40°F (−40°C) to 140°F (60°C). For bimetal thermometers, the upper limit for the silicone case filling is 500°F (260°C).

However, there is one main disadvantage of using a pressure gauge with dampened movement: By preventing the pointer shaft from shaking, other parts of the movement actually experience a higher impact from the vibration. As a result, such gauges in high-vibration applications will experience an even shorter service life compared to the same gauge with a dry case and standard movement, due to the increased wear and tear on the moving parts. Therefore, we recommend dampened movement technology only when liquid-filled gauges are not a viable option.

Choosing Among Dry, Liquid-Filled, or Dampened Movement Instruments

When buying industrial instrumentation, should you go with a traditional dry case, a dry case with dampened movement technology, or a liquid-filled case? Because each industry and process has unique requirements, the best approach is to contact the specialists at WIKA USA for expert advice. We will help you decide on the best pressure or temperature solution for your application and budget.