The helical design has been used in a variety of applications to dampen flow-induced forces that can damage equipment. WIKA uses the same concept to stabilize thermowells and as an efficient and economical way to prevent thermowell mechanical fatigue and failure. One of WIKA’s product experts explains it all in Flow Control magazine.

The August 2018 issue of Flow Control features an article about how to protect thermowells from vortex-induced vibrations and mechanical fatigue. It was written by Adam DeLancey, WIKA Product Manager for Electric Temperature Measurement and a seasoned veteran on the topic of temperature measurement solutions.

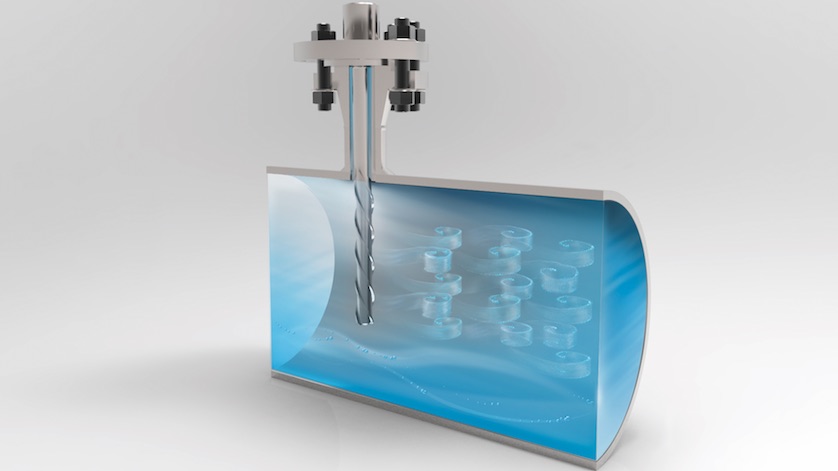

In his article, DeLancey explains how, under certain flow conditions, the fluid inside the pipeline can create vortices. These vortices produce periodic lift and drag forces around the thermowell that make it shake. If the frequency of these vibrations is close to the thermowell’s natural frequency, the thermowell can “lock in” and go into resonance. It is therefore very important that thermowells pass wake frequency calculations that take into account dynamic stresses.

What to Do If the Thermowell Does Not Pass Wake Frequency Calculations?

Traditional methods for reducing thermowell vortex-induced vibrations include:

- Shortening the insertion length

- Increasing the root diameter

- Increasing the tip diameter

- Adding support collars

Many times, however, these adjustments do not reduce vibrations enough to allow thermowells to pass wake frequency calculations, or are very expensive and time-consuming to implement.

WIKA’s Helical Thermowells: An Efficient, Affordable Solution

Engineers have used helical strakes for decades to reduce vortex-induced vibrations in a variety of industrial applications, including on/offshore risers and platforms, and cables in suspension bridges. WIKA applied this same concept to its ScrutonWell® design. The result? An easy to install thermowell that reduces the amplitude of the vibrations by more than 90%. There’s no need to change the dimensions of the thermowell or perform expensive and time-consuming retrofittings to pass wake frequency calculations.

The ScrutonWell® helical design can be used in all solid-machined thermowells and with a variety of process connections. This type of thermowell works particularly well in petrochemical processes, on/offshore applications, and plant construction. It is also the recommended option for critical measuring points and high process loads where conventional thermowells are not suitable

In the article, DeLancey mentions one of the many real-life cases where the ScrutonWell® design proved to be an efficient and affordable solution. Thermowells in the crude units that a major oil company was updating were having problems with vortex-induced vibrations. Traditional methods were not enough to reduce the vibration. WIKA’s ScrutonWell® design neatly solved the problem. Now the crude units not only pass wake frequency calculations, but they have room for future upgrades.

Thermowells are a fast and inexpensive solution for protecting temperature sensors in oil and gas processes and other industrial applications. Click hereto read DeLancey’s article. For more information about thermowells, the ScrutonWell® helical design, and other temperature measurement solutions, contact the experts at WIKA USA.

[contact-form-7 id=”14552″ title=”Blog Contact Form”]