Leak testing is an essential step in the production of pressure gauges, as airtight pressure systems prevent fugitive emissions of hazardous and/or expensive process media. WIKA’s helium leak tests greatly exceed international, European, and U.S. standards.

In numerous manufacturing lines, from hydraulic units to HVAC components, an important part of quality control is to test instruments for leaks. There are numerous ways to do this, from simple yet imprecise to technically demanding and highly sensitive:

- Water bath test (bubble test or dunk test) – the most common method

- Pressure drop test (pressure decay test)

- Vacuum drop test (vacuum decay test)

- Mass flow test

- Helium leak test (tracer gas leak test)

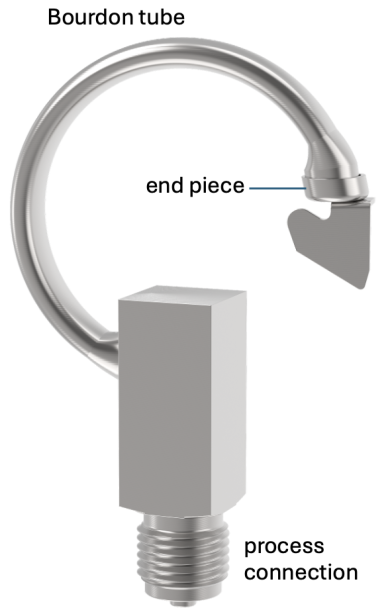

A typical pressure gauge measuring system includes the process connection, the Bourdon tube, and the end piece.

The Importance of Leak Testing

In a typical stainless steel Bourdon tube pressure gauge, the measuring system includes the process connection, the Bourdon tube, and the end piece. These three components are permanently joined through welding during the manufacturing process, then undergo a leak test. Once the pressure gauge is in use, the measuring system is exposed to internal pressure and is in direct contact with the process media. If any part of the gauge is not airtight, the process medium will escape.

A leakage in the measuring system can have serious consequences:

- Danger to personnel and the environment due to fugitive emissions of flammable, explosive, or toxic substances

- High financial cost of losing expensive process media

- Unplanned repair costs, downtime, or even plant shutdown

High leak tightness in pressure gauges significantly enhances process safety, ensures reliable operation, and minimizes downtime. For these reasons, a critical quality feature of pressure measuring systems, especially the gauges used in high-integrity industries like semiconductor manufacturing, is a test capable of detecting even the tiniest leaks.

WIKA’s Helium Leak Test: 5,000 Times Tougher Than the Industry Requirement

Tracer gas leak testing is one of the most sensitive and reliable methods for detecting leaks in stainless steel pressure systems. Helium is the most effective tracer gas due to its small atomic size, which allows it to easily pass through even submicroscopic cracks and holes. WIKA uses this proven, industry-leading method.

The production of WIKA stainless steel pressure gauges includes an integral helium leak test with a leakage rate of 1 x 10-6 mbar · l/s. During this test, the measuring system is pressurized with helium inside a previously evacuated chamber. A leak detector then scans the vacuum chamber for escaped helium. This method is highly precise and technically demanding, and it comes with substantial costs for the manufacturer – from the initial investment in specialized testing equipment and its ongoing maintenance to the use of helium, an expensive tracer gas.

Relevant industry standards – EN 837-1 (Europe), ASME B40.100 (U.S.), ISO 5171 (international) – require a leakage rate of only 5 x 10-3 mbar · l/s to be considered leak tight. Most companies surpass that with the water bath test or the pressure drop test, which have a leakage rate of 1 x 10-3 mbar · l/s. For this reason, these two methods are the most common leak tests on the market.

The helium leak test exceeds both. With a leakage rate of 1 x 10-6 mbar · l/s, it is 5,000 times more sensitive than the industry standards, and 1,000 times more sensitive than the water bath test or the pressure drop test.

Due to the expense, most instrument manufacturers offer helium leak testing as an option for an additional fee. At WIKA, however, the helium leak test is a standard part of quality assurance for stainless steel pressure gauges and transducers. This extremely high standard is critical for high-integrity systems where even submicroscopic leaks can cause contamination, pressure loss, and/or safety hazards.

The difference is striking. This example, of ethylene at a process pressure of 10 bar (145 psi), shows the practical implication of different leak rates:

Leakage rate in mbar · l/s | Hole diameter | Gas leakage over time | Gas loss |

5 x 10-3 | ~ 6 µm | 1 cm3 gas loss in 1 minute | 497 liters |

1 x 10-6 | ~ 0.1 µm | 1 cm3 gas loss in 4,320 minutes (3 days) | 0.1 liters |

WIKA is committed to the safety and efficiency of numerous industrial applications, all while helping our customers save money in both the short term and long run. Because the helium leak test offers the greatest possible protection against media leakage, WIKA uses it during the standard production for our stainless steel pressure gauges and transducers.

WIKA USA, Your Partner for Quality Instruments

WIKA’s industry-leading craftsmanship and above-average standards have made us a trusted instrument supplier for companies around the world. What’s more, over 95% of our pressure gauges are manufactured in Lawrenceville, Georgia, at our state-of-the-art facility certified to ISO 9001 (for quality management systems) and ISO 17025 (for testing and calibration). Contact the product specialists at WIKA USA for more information about helium leak testing and the role that airtight instrumentation plays in plant safety and process efficiency.

For more information, contact WIKA USA.