Industrial Internet of Things (IIoT) is the process industry’s most powerful tool for future-proofing its capabilities. From predictive maintenance of rotating machinery to smart monitoring of remote sites, an IIoT pilot project helps businesses gain greater intelligence from their data.

Industrial IoT is not just another trendy technology. It is the backbone of future-proofing business models in sectors that demand efficiency, resilience, sustainability, and innovation.

Process industries are excellent candidates for IIoT, as they face several market challenges:

- Complex, resource-intensive operations

- Shifting geopolitics that affect supply and demand

- Stricter regulations at all levels: municipal, state, national, international

- Mounting economic uncertainty and pressure

- Intense global competition, especially from markets with cheaper labor costs

While IIoT is not a panacea, it does give companies the tools to better adapt, optimize, and innovate in ways that were not possible even just a few years ago. But where and how to start?

Digital transformation projects can seem daunting, with many technologies and approaches available. There are also potential hurdles to implementing IIoT: lack of technical know-how on your team, financial and operational constraints, cultural resistance to change.

Whether your company is in the exploratory stage or is already committed to IIoT, this article gives you a step-by-step guide on how to get started on creating smart factories and facilities. Following that are scalable IIoT solutions that span the entire value chain, including ideas for initial projects where automated, connected systems would have the most impact.

What Is Driving Industrial IoT Growth?

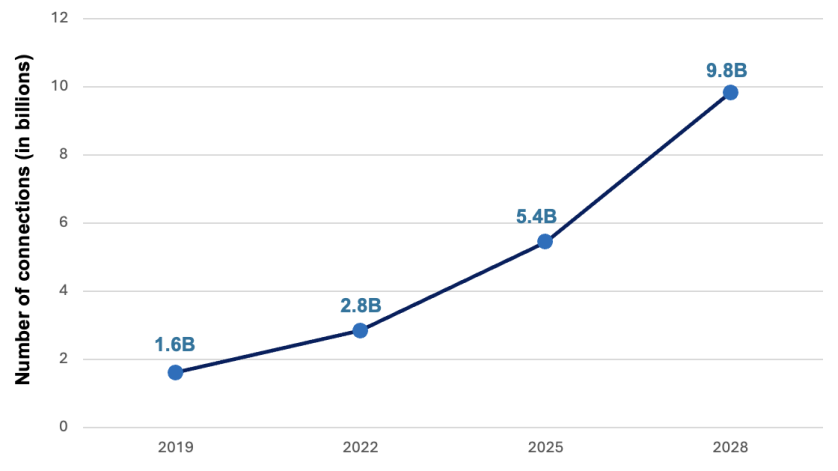

Fig. 1: Actual (2019, 2022) and projected (2025, 2028) number of IIoT connections globally

The number of IIoT connections is projected to reach almost 10 billion by 2028 (Figure 1, Statistica, March 2024). The main driver of this trend is digital advancements: faster processing speeds, reduced latency, artificial intelligence, and the ability to support an almost unlimited number of connected devices simultaneously. Another accelerator is easy retrofitting, as specialized sensing and networking technologies make it easy to upgrade existing sensors for IIoT compatibility.

Another reason the number of IIoT connections doubles every few years is that the market has long rewarded businesses that find ways to increase productivity. Henry Ford changed the game in 1913 with the moving assembly line, which eventually led to higher wages, shorter shifts, more affordable cars, and greater profitability for his company. More than a century later, the game changer is IIoT, and it couldn’t have come at a better time. Supply chain issues have led many manufacturers to onshore or “nearshore” production and processes. Governments are also incentivizing bringing production back home. With increasing costs in labor and materials, greater efficiencies in machines and operations can mitigate those expenses. Advanced connectivity also reduces unnecessary – and costly – downtime.

Of the U.S. manufacturing executives that Deloitte Insights surveyed in 2024, 92% said they believe “smart manufacturing will be main driver for competitiveness over the next three years.” Five year earlier, 86% held that sentiment (Deloitte Insights, May 2025).

In short, IIoT is not a matter of if, but when.

Benefits of IIoT for Process Industries

Connected and automated systems offer real advantages to process companies that adopt IIoT.

- Continuous data analytics. Many sectors in the process industry – oil and gas, chemical and petrochemical production, pharmaceuticals, food and beverage, power generation, water and wastewater treatment – operate around the clock. The sensors, control system, and machinery running 24/7 generate tremendous amounts of data. IIoT gathers and analyzes this information stream to optimize processes, improve quality, and enhance efficiency.

- Early warning system. Unscheduled downtime leads to not only operational disruptions, but significant financial losses. IIoT-enabled sensors and analytics platforms enable predictive maintenance by flagging potential issues in performance before they can snowball into equipment failure, product losses, and/or safety risks.

- Better regulatory compliance. Businesses in the process industry often handle hazardous materials or have stringent sanitary and hygienic requirements. With 24/7 monitoring and remote management, plants can react immediately to deviations to ensure a work environment that adheres to safety standards.

- Optimized energy usage. Process facilities are heavy consumers of fuel and other resources. IIoT-enabled sensors and systems can track energy usage, identify areas of inefficiency, and help operators reduce waste. Efficient fuel consumption boosts profitability and is better for the planet.

- Flexibility and scalability. It is easy to reconfigure and customize wireless sensors as processes change. Adding new sensors is equally simple, often just plug-and-play and taking only a few minutes to become functional. And what works in one facility is easily transferrable to multiple sites, thus allowing companies to standardize operations.

- Integration with legacy systems. Many in the process industry already have SCADA (Supervisory Control and Data Acquisition) or DCS (Distributed Control System) and their associated hardware. Rather than replacing them, IIoT complements these and other automation systems with cloud computing, advanced analytics, and machine learning, thereby unlocking additional value and return on investment.

- Digital twinning. A virtual replica of physical processes allows engineers to simulate functions, test scenarios, and optimize production without disrupting real-life operations, but it is extremely expensive and time-consuming to create a complete digital twin using legacy measurement methods. IIoT sensors can accomplish this at a fraction of the time and cost.

- Better customer service. Your customers are increasingly calling for greater transparency, customization, and quality assurance. IIoT allows companies in the process industry to provide all three with traceability, tailored solutions, and production oversight.

4 Things to Keep in Mind When Adopting IIoT

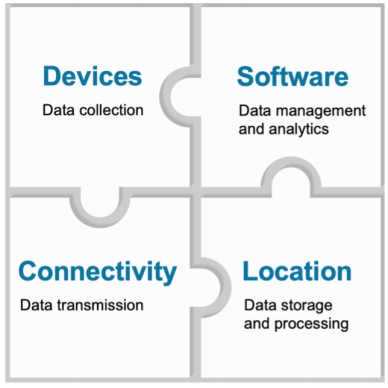

Four critical areas of IIoT integration

It is becoming increasingly clear that IIoT adoption needs to be part of a process company’s strategic plan. The IIoT value chain covers every stage, from the physical instruments that gather data to the business decisions and outcomes that arise as a result of data analysis.

As you explore IIoT integration, consider four critical areas: devices, connectivity, location, and software.

1. Devices: data collection

Electronic instruments sense the process status, assess its condition and detect anomalies, and then transmit the status. For extra flexibility in device installation and placement, consider battery-powered wireless sensing and transmission.

2. Connectivity: data transmission

Look for IIoT solutions that support industrial network standards, such as

- LoRaWAN® (Long Range Wide Area Network)

- LTE/5G, LTE-M, NB-IoT, and other mobile technologies

- Private LPWAN (Low Power Wire Area Networks)

For best results, invest in professional networking planning and hosting. Standardization and interoperability ensure that devices and gateways – if sourced from different vendors – work seamlessly together.

3. Location: data storage and processing

All the data that’s collected has to be stored and undergo advanced processing somewhere. The location depends on your priorities. The advantage of cloud-based storage is that it’s quick and easy to set up private networks without affecting the company’s current IT infrastructure or having to invest in additional hardware. The advantage of on-premise storage is that the data is centralized and the software is deployed on local company servers, which your IT team controls directly. Since on-prem allows complete control over data, hardware, and software configurations, it is the preferred strategy of companies that prioritize data ownership and/or are in highly regulated industries, where compliance is critical.

4. Software: data management and analytics

The more powerful the software, the more a company can glean insights from its collected data. Look for applications that enable:

- Remote monitoring

- Customization

- Predictive maintenance (due to machine learning)

- Advanced device management

- Integration with existing operating systems and IT systems

- Analytics and visualization

- Asset management and process improvement

How to Begin Implementing an Industrial IoT Solution

To navigate the complexities of IIoT implementation, partner with a company with expertise in all four critical areas: devices, connectivity, data storage and processing, and software. After zeroing in on a provider, work together to find a suitable pilot project. It should be small yet important, to better assess IIoT’s potential impact within a specific process or function. By focusing on a clearly defined use case, companies can gain valuable insights while limiting risk. To further minimize risk, cost, and complexity, the pilot project should integrate existing infrastructure whenever possible.

Steps to identifying a pilot project

First, determine a critical process or asset. Look for an area where production has suffered loss due to limited transparency, hard-to-access measuring points, or missing status information – all conditions that lead to repetitive steps and unstructured warehouse management.

Second, the pilot project should incorporate a remote site. This would allow you to test IIoT’s capability to centralize and remotely monitor data, assess the wireless network’s integrity, and evaluate a cost-effective maintenance strategy.

Third, keep scalability in mind. That way, if you’re happy with the pilot project, you can easily replicate the IIoT system to multiple assets or processes with the same or similar requirements.

The Roadmap to IIoT Implementation

The success of any project is contingent upon proper planning – one that aligns stakeholders, defines priorities, and helps manage complexities from the outset. Here is an overview of the roadmap as you start down the journey toward Industrial IoT.

The seven steps of IIoT adoption and implementation

- Identify the main challenges that your operation currently faces. Where are the pain points? What could be improved with better data?

- Assess the various IIoT options available in the market and the proposals that you receive from IIoT solutions providers.

- Make your decisions based on your top criteria, which could include financial impact, quick wins, and/or scalability.

- Prepare your team for new systems and workflows with onboarding and training. The more they understand the benefits of IIoT, the less resistant they will be to the change. Note: Be prepared to address concerns over job loss.

- The chosen solutions provider arrives at your facility to install the devices, control systems, and other related infrastructure.

- As the IIoT system rolls out, support your team during this transition period. At the same time, evaluate all aspects of the new procedure, adapting and adjusting and necessary.

- After the trial period, look at what worked and see where you can scale up the proven IIoT solution. Then identify the next operational challenges and work with your chosen vendor regarding IIoT options.

This series continues with ideas for pilot IIoT projects, including some challenges of implementation and their solutions.

Contact WIKA USA with questions about IIoT in the process industry.