Insulating gases – not just pure SF6 but also SF6 blends, N2, g3, and others – protect switchgear from failure. WIKA is a leader in remote sensing solutions that help power transmission and distribution companies monitor the quality and quantity of these gases.

Medium- and high-voltage switchgears can be insulated using different medias: oil, dry air, and other gases like sulfur hexafluoride (SF6) and new mixtures. The traditional and most effective insulator is SF6, but its use comes with several hazards, especially as this synthetic fluorinated compound has a global warming potential (GWP) of around 24,000—the highest of any known gases. (For reference, carbon dioxide has a GWP of 1.)

For the power transmission and distribution (PT&D) businesses that use SF6, they must monitor density to detect leaks, and periodically analyze the gas to detect the presence of contaminants. But even as many companies still rely on this gas to insulate switchgear, they do realize its role in climate change and are looking into SF6 alternatives.

Reasons for Failure in Gas-Insulated Switchgear

Most power plants and substations use air or a gas to insulate their switchgear. While air is abundant, non-toxic, and has 0 GWP, it is not as effective in quenching arcs. As a result, the compartment in air-insulated switchgear (AIS) has to be about three times as large as those for gas-insulated switchgear (GIS).

Both AIS and GIS are susceptible to issues that reduce their effectiveness and lead to switchgear failures.

Air insulation:

• Dirt and dust

• Contact resistance

• Overload

Gas insulation:

• Gas leakage

• Humidity, a potent impurity for SF6-insulated switchgear

• Decomposition products, many of which are toxic and will corrode GIS

Monitoring the insulator’s condition is a key step in preventing potentially dangerous situations. AIS operators should monitor the air’s partial discharge status, temperature, and humidity. For GIS, it is important to monitor the gas’s pressure, temperature, density, and humidity.

Switchgear has a typical life span of 20–50 years, with gas-related failures increasing sharply 15–25 years after installation. Therefore, monitoring is especially key during the second half of the equipment’s lifetime.

Reactive vs. Proactive Maintenance of Gas-Insulated Switchgear

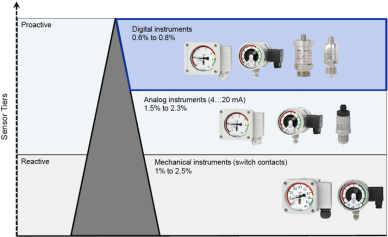

There are two approaches to monitoring the condition of GIS.

Reactive approach

In this approach, a mechanical instrument, such as a switch contact, sets off an alarm when the gas density has dropped to a certain level. In other situations, technicians manually read the gas density monitor on a predetermined schedule. Technicians then take corrective actions as necessary, such as:

- Dehydrating the gas while the switchgear is operating

- Repairing a leak and refilling the gas compartment

Mechanical instruments have an accuracy of 1–2.5% of span.

For humidity, technicians might manually analyze the gas periodically (every 1 to 6 years) with a portable test instrument.

Proactive approach

Both analog (4…20 mA) and digital instruments offer an earlier warning system with remote capabilities.

- Analog instruments continually monitor the gas density in GIS and transmit that data to a control room or another central location. Analog instruments have an accuracy of 1.5–2.3% of span for compensated pressure.

- Digital instruments continually monitor not just the gas density, but also the parameters of pressure, temperature, humidity level, etc. This gives a more complete picture of the insulating gas’s condition. Digital instruments have an accuracy of 0.6–0.8% of span.

The more parameters that a sensor can detect and transmit in real-time, the better operators can react to changes in the insulating gas’s condition and take steps to avoid safety issues. Besides remote monitoring capabilities, analog and digital sensors also allow for gas condition forecasting and predictive maintenance.

Gas Condition Forecasting: A better way to protect assets

One-time raw measurements of gas density can give a false or misleading picture of an asset’s performance, leading to misjudgments such as unnecessary or insufficient maintenance. Changes in ambient temperature and humidity, which vary constantly, are also hard to detect when measurements are taken sporadically or periodically.

With continuous monitoring, operators get not only a truer picture of the gas’s current condition, but also its evolution. They can use the data to gain a deeper understanding based on historical data, then use this knowledge for predictive maintenance and other next steps. And if smart sensors are used, the instrument will automatically compensate for ambient conditions to arrive at an accurate gas density.

Data quality in gas condition forecasting

Ambient conditions (temperature and humidity) and event anomalies have a notable impact on the precision of forecasts. In this figure, we see that a large ambient impact, combined with an anomaly early on in the data collection, makes for a very uncertain and imprecise forecast. The same ambient condition but without the anomaly results are more precise. A small ambient impact produces the most precise forecast.

Adding to the complexity, humidity has a complicated correlation with temperature. The humidity condition of an asset can be misjudged when only the raw measurements are taken into account. Furthermore, every compartment has its own unique correlation between humidity and temperature. This correlation can be extracted from historical data and compensated for. Thus, a temperature-compensated gas density can be forecasted with precision.

Since both data quality and temperature compensation have a significant impact on the precision of a forecast, it is necessary to use smart sensors with high accuracy and consistency, and to work with a provider who understands how to pre-process, manage, and interpret the data.

Smart Sensors for the Remote Monitoring of Insulating Gases

The more information that operators have about their equipment’s insulating media, the better they can prevent failures and hazardous conditions. WIKA offers sensors based on temperature and pressure that, with the proper configuration, are easily adapted to calculate the current density of different gases.

WEgrid, a wholly owned subsidiary of WIKA, offers a suite of smart sensors that forecast the condition of all types of insulating gases, including:

• SF6

• N2

• SF6/N2 mixture

• CO2

• O2

• CF4 (tetrafluoromethane)

• Helium

• Argon

• Air

• g3, a syngas with 3M’s Novec 4710

GD-20 gas density sensors

No matter the equipment or insulating media, our gas density sensors can be configured for that particular application.

WIKA offers several transmitters for reliable monitoring of SF6 and alternative insulating gases. One of them is the GD-20. The analog version focuses on gas density, transmitting a temperature-compensated pressure reading via a 4…20 mA output signal. The digital version has an RS-485 interface that communicates using the MODBUS® RTU protocol, and provides data for pressure and temperature in addition to gas density.

The GDHT-20 is another high-quality transmitter, capable of everything the digital version of the GD-20 can do with the addition of measuring the insulating gas’s humidity content. This additional parameter enables monitoring within the terms of the CIGRE directives for power systems, as well as IEC standards.

WIKA Specializes in Solutions for SF6 and Alternative Gases

While SF6 will remain the primary insulating gas for the near future, less harmful alternatives and other climate-friendly technologies are on the horizon. Governments are part of the push.

- In 2022, the European Commission proposed banning fluorinated greenhouse gases from new medium-voltage switchgear by 2026 and from high-voltage switchgear by 2031.

- About a dozen U.S. states have initiatives and regulations to phase out SF6-containing GIS.

WIKA is a global leader in instruments and equipment that analyze and monitor both traditional and alternative insulating gases. We also offer comprehensive project planning for PT&D businesses, from engineering and installation of equipment to data management and analytics using our proprietary software. Contact us for more information on how we can help your facility operate more safely and sustainably.

Discover why SF₆ plays a key role in gas-insulated switchgear – and how Elia Group, together with WIKA, is revolutionizing substation monitoring with innovative solutions such as the GD-20-W.

For more information, contact WIKA USA.