Most pressure gauges around the world have either an NPT or G (metric) connection for insertion into processes. It is useful to know their differences – and also how to recognize which type is in use – without having to remove the entire assembly.

Have you ever looked at a pressure gauge in a pipe assembly and wondered which connection type it has? Perhaps you have to replace a measuring instrument or need to buy a new one. One way to find out is to remove it from the installation and look at its threads, but this will result in downtime if the process is active. There is an easier way to tell whether a gauge has an NPT or G connection.

1/4-inch NPT connection

NPT Connections in Pressure Gauges

Most of the time, the answer depends on geography. In the U.S. or Canada, the pressure gauge will most likely come with an NPT (National Pipe Tapered) connection. This thread type, standardized by ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers), is typical among North American measuring instruments, found in piping systems, pumps, compressors, plumbing systems, mobile working machines, and many more applications.

Male (external) NPT connections are somewhat conical, with the diameter of the threads decreasing slightly from socket to tip. Tapered threads seal along the flanks of the thread. Due to the spiral leak path, however, Teflon® tape (PTFE) or a sealing compound is required to create a good seal. The most common sizes for pressure gauge connections in the U.S. are ⅛-inch NPT, ¼-inch NPT, and ½-inch NPT.

The U.S. and Canada also use parallel threads like the NPSM (National Pipe Straight Mechanical) connector. However, this thread type is typically found as a female (internal) component in non-pressurized devices like thermowells.

The tapered shape of the NPT threads allows users to continue turning the connection several more degrees after making the seal – until the instrument reaches the desired position. Tightening, though, has to be done with care: Too much compression can lead to galling, and over-tightening can damage the threads. These situations are problematic in applications that require regular installation and removal of the pressure gauge.

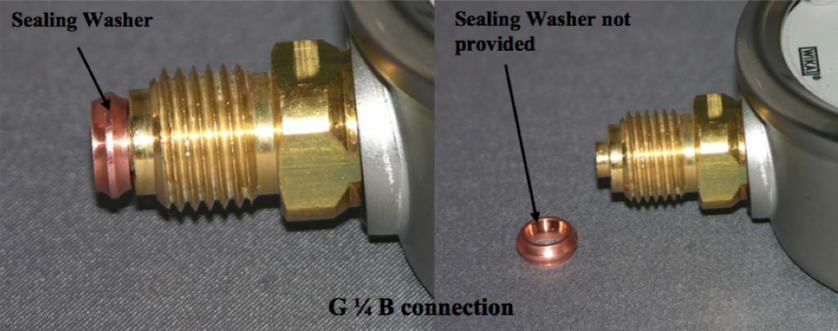

G 1/4 B Connection

G Connections in Pressure Gauges

If the pipe assembly is in Europe, Asia, or Latin America – basically anywhere else in the world but the U.S. and Canada – the pressure gauge will very likely have the straight threads of a British Standard Pipe Parallel (BSPP) connector, denoted by the letter G*. The tapered variants from the BSP classification system are denoted by ISO7, for example R1/4-ISO7.

They are often referred to as metric connections because they are used in the metric system and the dimensions are based on metric measurements. G connections have a straight body (constant diameter) with parallel (straight) threads. The main purpose of the parallel threads is to contain the pressure, which allows for regular installations and removals without damaging the thread. A sealing washer is required to seal the connection. As sealing of the connection takes place on the washer and not on the thread itself, no sealing compound or PTFE tape is required.

Sealing washer on a pressure gauge with a G connection

Since the thread of a G connection will bottom out at the wrench flat, no threads are left exposed. Once the connector bottoms out to make the seal, the positioning of the instrument cannot be changed. To avoid the problem of awkward gauge positioning, use a “crush washer” and hand-tighten the connection. At the resistance point, approximately 1½ turns are left before the crush washer flattens out. This leeway allows the user to fine-tune the pressure gauge’s final position with a wrench**. If the position of the instrument is not critical, a flat washer can be used instead.

Eyeballing the Difference Between NPT and G Connections

When placed side by side, the difference between the two connection types is clear. The NPT thread is slightly tapered, while the G connection is straight. Another obvious visual: The G connector ends with a small protrusion (nipple), used to center the gasket. If calipers are handy, a third method is to measure the angle between threads: NPT threads are 60°, while BSP threads are 55°.

But how about when the pressure gauge is already inserted into the process? Is there an easy way to tell which connector type an instrument has without removing it? Yes. Because a G connection bottoms out, no threads are visible. In an NPT connection, a few threads or exposed PTFE tape can be seen.

NPS vs. G Connections

| NPT connection | G connection |

Thread shape | Slightly tapered | Straight |

Tip of thread | Blunt | Small protrusion (nipple) |

Thread angle | 60° | 55° |

Visual when assembled | Visible thread or PTFE tape | No exposed thread |

The pressure experts at WIKA USA understand national and international measurement standards, pressure gauges, and which ones are best suited for your industrial processes. Contact us with your questions.

* Even though BSP is now based on metric measurements, this system’s names still reflect their imperial origins. That’s why G and R connection names range from 1/8 to 6 (inches), rather than 6 to 150 (mm). As for the “A” or “B” in some name, such as the common G ¼ B connection type, the letter denote lets users know 1) it’s a male thread, as female BSP threads don’t have a final letter, and 2) its tolerance class.

** To avoid damaging the pressure gauge’s threads, regardless of the connection type, use the right wrench and use it only on the flat area of the socket. Also, never hand-tighten an instrument by the case or the housing.

The question I had/have is what happens if you have an NPT male thread and a G type female thread.

Can I screw the NPT male into a G female, and still have pressurized seal? Even using pipe PFTE tape if needed?

Hi Gary

Thank you for submitting your question to WIKA. We definitely advise against it, trying to use a 1/2″ NPT with a G1/2B counterpart. It is not a fit, and using the Teflon band is just like a band-aid the can come off at any moment. It for sure does not create a pressure-tight seal. If you have a gauge with a metric G1/2B thread and your port is NPT or vice versa, try to find an adaptor. I am sure you’ll find them at industrial supply places like Granger, MSC, etc. Also, for the G1/2B connection, you need a gasket because the thread bottoms out and that’s where you need to create a seal. I hope this answer helps, and thank you for checking out WIKA.

Hardy

Can I used a Male ISO 1/2” BSPP (G) to a Female 1/2”-14 NPSM? Water application @ 130 psi max water pressure. Relying on a gasket, thanks

Hello Cesar,

Thank you so much for your interest in WIKA pressure gauges. This is a good question.

The pitch of the two connections is the same 1.814, threads per inch 14 are the same, however, the angle is different NPSM 60°, G1/2B (BSP) 55°. In a way, it looks like that it could work but in general, we do not recommend combining two dissimilar threads with each other. However, I am not sure if you can actually get a pressure gauge with a 1/2-14 NPSM connection. We do not have one.

I hope the answer still helped you somewhat.

Best regards,

Hardy Orzikowski

I am reaching out because Hardy Orzikowski is an amazing name. That it all. Thanks

I need to replace an existing DPG that has process connection 2xG1/4 female.

The supplier proposed 2×1/2″NPT process connection.

Will the supplier proposal fit into the existing process connection?

Hi Tula. Thank you for your comment. A product manager should be reaching out to you shortly if they have not already.

Im trying to put a pressure gauge on a 55 gallon drum ,i put pressure in the tank but not one pressure gauge will work ,i put the gauge on the top of the tank ,right on the lid , and it wont give me the pressure .?????

Dear Mike, thank you for reading the WIKA blog. Not knowing the exact application and set-up it is almost impossible for us to diagnose the issue from a distance. If everything is piped and connected correctly and provided that the right pressure range was selected you should see a reading on the pressure gauge. At this time won’t be able to tell you why the pressure gauge will not give you a reading.

Best regards,

Hardy Orzikowski

( G 1/2″ A)-Male as per ISO-228-1 tolerance A is required. What is the difference between G 1/2 A and G 1/2 B. where can we refer the tolerance levels?

The A form used to be the norm in Germany when the DIN 16005 was the official standard. At that time it was referred to as R1/2”. The official standard changed to the EN 837 when the European Union was formed and they decided to use the same standards in every country. The new standard dictated that the BSPP threads would now use the B form. The only difference between the two thread forms is that the A form has a slightly tighter thread tolerance than the B form. Both the A and the B forms connect to the same female thread and seal without a problem in combination with a sealing gasket. WIKA uses the B thread form because it is now the standard in Europe.

Best regards,

Hardy Orzikowski

for the WIKA PG 28 model, with G1/2B connection, do we have the Hastelloy sealing rings?

Dear Vivek, unfortunately here at WIKA we do not have a Hastelloy sealing ring. As an alternative we could offer a PTFE sealing ring, which is often used for aggressive media but ultimately it is the customers decision what sealing ring material they are using. Thank you for your question.

From what I read, the sealing of the G Connection is at the thread itself rather than the thread, therefore, is it correct to state that the depth of the female side of the connection in the process flange need to be accurate for the male G connection to “crush” the washer to provide a seal

Hello Andy, you are absolutely correct. The metric threads are basically bottom out. They typically have a little spigot (nipple) at the bottom of the thread to keep the gasket or crush gasket centered. For the G thread it is therefore critical that the counterpart meets the same standard. If female part is too long or too deep, the gauge will bottom out before it seals.

Hi, we have purchased S11 model PT which has G1/2″ Male connection. We are not able to find the matching female fitting in any of the reputed manufacturers. The problem is the length of the process connection is 23mm as per PT drawing and the female fittings have maximum depth of approx. 15-17mm. Can you suggest proper fittings?

Hi Sumesh, your question has been passed along to our product managers and they should have an answer for you soon.

Hello,

My name is Jerardo, I am writing because our company recently purchased and just received our WIKA CPG1500 with G 1/2 B connection. We are trying to source the Male adaptor so that we can connect our pressure gauge and commence with its operation. Will you please guide us in the right direction as to what the adaptor or connector name is and where we can purchase it here in Southern California, USA.

Hi Jerardo! Thank you for reaching out with your question. WIKA USA does have an adapter available that goes from G1/2B male to 1/2″NPT male in stainless steel.

However, we do not have it available from stock in Lawrenceville. It will take approximately 3 – 4 weeks delivery time. In addition to the adapter, you would also need a flat gasket made from stainless steel or Teflon to seal the adapter to the G1/2B thread. The P/N for the adapter is 906492.To order these parts we recommend you contact your WIKA USA distributer to fulfill this request. If you have any other questions, please email [email protected] or your distributer for further information.

Best,

WIKA USA