Load pins act as both structural connecting components and high-precision force measurement devices. By replacing existing standard pins, these specialized force transducers promote operational safety and machine efficiency, even in harsh working conditions.

Updated Jan. 12, 2026

Clevis and other structural pins securely connect two machine components, such as in hoist and crane systems and in towing winches. A load pin also connects two component, but with the additional ability of measuring and monitoring the force acting upon it. For this reason, load pins are also called clevis load pins.

WIKA load pins

What is a load pin?

A load pin is a type of load cell that looks and acts like a regular cylindrical pin connecting two components, but with the addition of a strain gauge that precisely measures the tensile and compression forces acting on the sensor. By taking the place of non-measuring retaining bolts, load pins are easy to integrate into existing systems.

How does a load pin work?

A load pin connects two force-transmitting machine elements and measures the force acting on its sensor.

Where are load pins installed?

Load pins can be used anywhere with a pivot or joint where loads naturally pass through a pin connection.

Load pins are installed at the connection point between two force-transmitting elements, taking the place of clevis pins and other conventional retaining pins. They can be used anywhere with a pivot or joint where loads naturally pass through a pin connection.

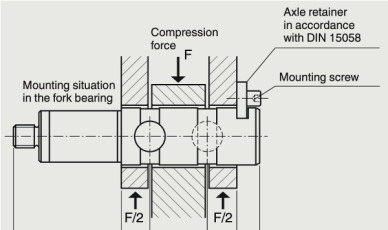

These specialized force transducers are mounted axially as well as against rotation. A microscopic gap (~1/5 of a millimeter) between the axle retainer and the slot enables free bending in the thrust bearing.

Which industrial applications use load pin load cells?

Load pins are widely used in lifting gear such as boom cranes, offshore cranes, anchor-handling systems, and other lifting machinery to prevent dangerous overload conditions. These force transducers are also found in guide pulleys and roller bearings, industrial weighing technology, and production automation.

Clevis load pins are used in many industries to prevent overload and improve safety:

- Oil and gas, especially offshore upstream applications

- Chemical/petrochemical plants

- Mobile working machines

- Machine building and automation

- Stage equipment and theater technology

- Maritime applications

- Shipping ports

What are the advantages of using load pins vs. other types of load cells?

As mentioned above, load pins can directly replace non-measuring structural pins. Load pins are also highly customizable, coming in a variety of sizes, shapes, and load capacities. These attributes mean that clevis load pins can be integrated directly into almost any force flow without taking up additional space or requiring complex redesigns.

In addition, load pins are low-maintenance, thanks to their rugged sealed construction, high IP ratings, high-strength and corrosion-resistant materials, and excellent resistance to shock and vibration – especially if they use thin-film technology where the sensing material is laser-welded onto the body.

Why use WIKA load pins?

Engineered, manufactured, and calibrated at a state-of-the-art facility in central Ohio, our load pins offer numerous advantages:

- Thin-film strain gauge option for excellent temperature characteristics, long-term stability, and higher resistance to shock and vibration

- Made of high-strength 17-4 stainless steel

- Integrated amplifier

- Reverse polarity protection, resistance to overvoltage and short circuits

- Standard and optional approvals: UL, ATEX, IECEx, EAC, and more

- Fast turnaround times and responsive customer support

- Customizable designs

- Factory calibration

- Small or large batch runs

WIKA Sensor Technology offers two series of high-quality load pins with thin-film technology.

- F5301 (standard) and F53C1 (with UL or ATEX approvals), up to up to 200 kN

- F5308 (standard), F53C8 (with ATEX approval), F53S8 (safety version), heavy-duty versions, from 0…10 kN to 0…10,000 kN

Whether you are retrofitting existing structural pins with load pins or are creating a new system, you need specialized force sensors. Our force specialists look forward to working with you to custom-design load pins and other force solutions for your particular applications. Contact us for more information.

Products mentioned in this article

• F301/F53C1 load pin with thin-film technology

• F5308/F53C8/F53S8 load pin with thin-film technology, heavy-duty version

Cost?

Hey Larry,

Thank you for commenting on our blog. If you would like to find out more about the cost of our load pins feel free to reach out to a sales rep or distributor found here.