While measuring gauge pressure is sufficient for most industrial applications, sometimes it is necessary to use an instrument that displays absolute pressure, as this reading does not fluctuate depending on altitude or weather conditions.

- The two sides of a filter, to monitor its condition.

- Before and after an orifice plate, to measure a liquid’s velocity.

- The difference of high pressure and low-pressure tap in a sealed vessel, to measure the liquid level.

What might be harder is deciding whether to use an instrument that measures gauge pressure or absolute pressure.

Comparing Gauge Pressure and Absolute Pressure

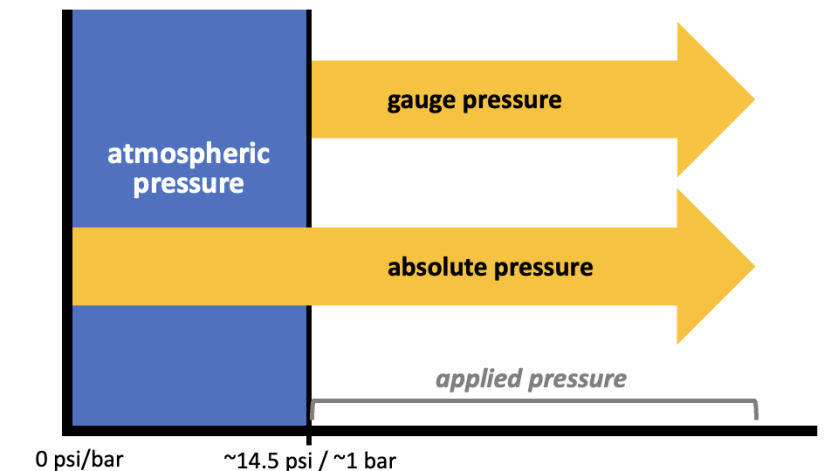

Pressure is usually measured by quantifying the deformation of a sensing element, where one side of the element is exposed to a reference pressure and the other side is in contact with the process media. If the reference pressure is atmospheric pressure (also referred to as ambient pressure, air pressure, and barometric pressure), the measurement is called gauge pressure or relative pressure.

If the reference side of the sensor is subjected to a vacuum, the measured value is called absolute pressure. In other words, gauge pressure is zeroed against the atmospheric air pressure (~14.5 psi / ~1 bar at sea level) while absolute pressure is zero-referenced against vacuum pressure (0 psi/bar).

Comparing gauge pressure and absolute pressure

In the above graph, if the applied pressure is 100 psi, a pressure gauge would read 100 psi while an absolute pressure gauge would read 114.5 psi absolute.

Thus:

- A pressure gauge displays just the applied pressure (above or below the atmospheric pressure).

- An absolute pressure gauge displays atmospheric pressure + applied pressure.

In countries that use imperial units (mainly the US), the typical unit for pressure is psi (pounds per square inch). This designation usually defaults to gauge pressure, and is sometimes labeled psig (psi gauge). Absolute pressure must be labeled as psia (psi absolute). Regardless of the unit used, WIKA’s absolute pressure gauges have “absolute pressure” printed on the dial face.

When to Use a Pressure Gauge vs. Absolute Pressure Gauge

Atmospheric pressure fluctuates depending on a location’s temperature, humidity, and altitude. For pressure applications that are not affected by changes in atmospheric pressure, a standard pressure gauge should be used. Such applications include hydraulic pressure, pneumatic pressure, and hydrostatic pressure.

However, use an absolute pressure gauge when any changes in temperature, humidity, and altitude must be factored into the measurement. These include:

- Aviation and aerospace applications

- Research, scientific, and calibration labs

- Vacuum packaging in the food and beverage and pharmaceutical industries

Ideal for monitoring the high end of a vacuum, absolute pressure gauges are referenced to a perfect vacuum. This reference can be either a capsule element inside the gauge, or a gas-tight chamber between the media and the gauge.

WIKA’s Absolute Pressure Gauges

To ensure proper measurements and the integrity of high-precision process, use a high-quality absolute pressure gauge that fits your application’s conditions.

300-2.75A absolute pressure test gauge

Series 300 absolute pressure gauges

Available in two nominal sizes, models 300-2.75A (2.75“) and 300-6A (6″) are capsule-type gauges for production and routine testing. The 2.75” gauge measure up to 100 psia, while the 6” one measures up to 30 psia.

Series 1000 absolute pressure gauge

The 1000-6A is a heavy-duty 6-inch absolute pressure gauge that can measure up to 500 psia. The references are an evacuated capsule for measurements in the 50 psia range, or an evacuated Bourdon tube for measurements in the 100 … 500 psia range.

Series 1500 absolute pressure gauge

The 1500-8.5A is our largest (8.5″), top-of-the-line capsule-type absolute pressure gauge. It is rugged enough to maintain a ±0.067% FS accuracy for high-sensitivity testing and production.

Note: Capsule-type gauges are used with dry gaseous media only, as liquids trapped inside the sensing element can create a hydrostatic load that inflates the pressure reading.

Absolute pressure gauge with diaphragm element

Absolute pressure gauge with diaphragm element

To measure the absolute pressure of wet gases, liquids, or aggressive media, use an absolute pressure gauge whose vacuum reference is isolated from the sensing element. Model 532.5X, a specialized type of diaphragm pressure gauge, are stainless-steel absolute pressure gauge with ranges as low as 0 … 20 mmHg absolute up to 0 … 300 psia and with high overload safety.

The diaphragm element is located beneath an evacuated (vacuum) reference chamber. As the gas or liquid travels up the stem and enters the media chamber, it deflects the diaphragm, which pushes the link that moves the instrument pointer.

For extra functionality, WIKA pairs the 532.5X absolute pressure gauge with switch contacts. Model 532.53+8xx is ideal for monitoring and controlling vacuum pumps, packing machines, and applications that need to determine the vapor pressure in liquids. Model APGT43 is our 532.54 absolute pressure gauge integrated with an electronic sensor for signal transmission. Dubbed the intelliGAUGE®, this device combines mA and V signal output with a local mechanical display that remains readable during power outages.

Smart Pressure Solutions for Industrial Applications

In addition to these high-quality absolute pressure gauges, WIKA also offers an array of digital pressure gauges, pressure sensors, and pressure transmitters that can measure absolute pressure.

We understand that with all the variables that go into selecting pressure instruments, it can be difficult to decide which ones are right for your particular application. For customized advice, contact the pressure specialists at WIKA USA.

Products mentioned in this blog:

• 300-2.75A (2.75“) absolute pressure gauge

• 300-6A (6″) absolute pressure gauge

• 1000-6A (6″) absolute pressure gauge

• 1500-8.5A (8.5″) absolute pressure gauge

• 532.52, 532.53, 532.54 stainless-steel absolute pressure gauge

• 532.53+8xx absolute pressure gauge with switch contacts

• APGT43 absolute pressure gauge with output signal (intelliGAUGE®)

[contact-form-7 id=”14552″ title=”Blog Contact Form”]