As more industrial machines and processes become interconnected, manufacturers need components that can talk to one another. WIKA’s A-1200 pressure sensor is the smart solution for future-focused automated factories.

The Internet of Things (IoT) is revolutionizing manufacturing facilities. Connected systems result in safer and more efficient processes, not to mention significant cost savings in the long run. But for “smart factories” to become a reality, components must have digital networking capabilities.

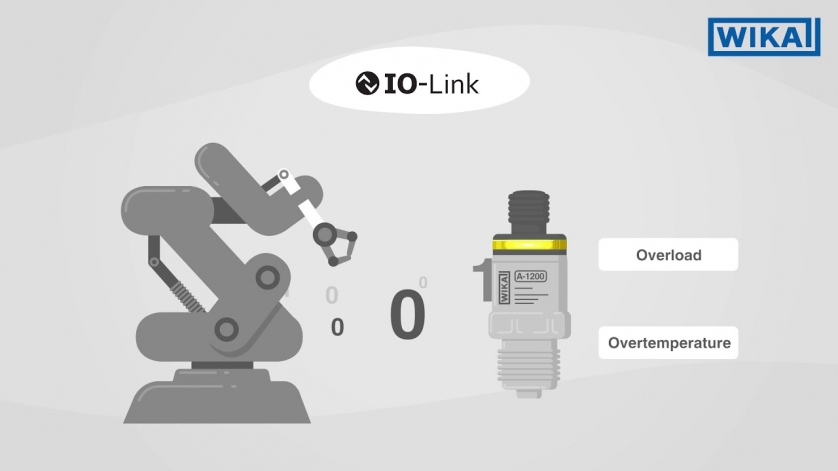

Model A-1200 pressure sensor with IO-Link

Pressure Measurement for Industry 4.0

WIKA USA is dedicated to automation, digitalization and data – basic requirements for Industry 4.0, or the fourth revolution in manufacturing. That’s why we created the A-1200 pressure sensor. With IO-Link for seamless integration with intelligent machines, this Industry 4.0-ready device communicates with other components in the production process for continuous pressure monitoring and automated switch control (NPN or PNP). IO-Link communication also allows users to remotely configure and adjust the pressure sensor.

A Smart, Sturdy Pressure Sensor

A 360° colored LED status display allows for quick diagnostics, troubleshooting, and maintenance: green = OK, yellow = critical state, red = error. The blinking function via IO-Link makes it easy for technicians to locate and replace a malfunctioning pressure sensor – an infrequent occurrence as the A-1200 is designed to withstand harsh conditions:

- Working temperatures from −40 to +125°C (−40 to +257°F)

- Shock loads up to 1,000 g

This short video gives a quick overview of the A-1200’s innovative features and capabilities. As always, WIKA experts are happy to answer any questions about electronic pressure measuring, digital connectivity, and preparing your machine building systems for the future.