WIKA USA proudly introduces the latest product in the Gayesco family of tubeskin thermocouple assemblies: the patent-pending TC59-T Tefracto-Pad®. This easy-to-install tubeskin sensor cuts the welding and inspection steps in half and results in a fool-proof installation.

The temperature measurement and furnace heater experts at WIKA continually look for ways to improve our products and save our customers time and money. One of the things we heard from them is that welding thermocouples onto furnace tubes is difficult and time-consuming. They said it was not easy to properly align the heat shield over the weld-pad, and they would appreciate tubeskin thermocouple assemblies that were easier to install.

The TC59-T, an Easy-to-Install Tubeskin Sensor

WIKA has decades of experience designing, manufacturing, and installing tubeskin thermocouples for major companies in the oil and gas, chemical, and petrochemical industries. Each new generation of our products offers improvements on the one before it, and our latest product combines maximum performance with minimal installation time.

The TC59-T, dubbed the Tefracto-Pad®, saves customers time and effort by making one-step installation possible. In this innovative assembly, the large weld-pad containing the thermocouple’s hot end fits precisely into the notch of our proprietary heat shield. As a result, customers no longer have to spend time welding two separate components and conducting two separate LPI (liquid penetrant inspection) tests. It takes just about an hour to weld a Tefracto-Pad® to the furnace tubeskin and complete the LPI.

Conventional shielded sensor installation | Time | One-step Tefracto-Pad® installation | Time |

Weld the pad to the tube | 5 minutes | Weld the assembly to the tube | 5 minutes |

Wait for LPI | ~45 minutes | Wait for LPI | ~45 minutes |

Verify LPI | 15 minutes | Verify LPI | 15 minutes |

Weld shield to tube | 5 minutes |

|

|

Wait for LPI | ~45 minutes |

|

|

LPI inspection | 15 minutes |

|

|

Total time | ~2 hours | Total time | ~1 hour |

How to Install the Tefracto-Pad®

Our innovative design makes alignment and installation fool-proof. Here are the simple steps:

- Locate an area on the furnace tube to install the sensor.

- Remove scale and rust from the selected location.

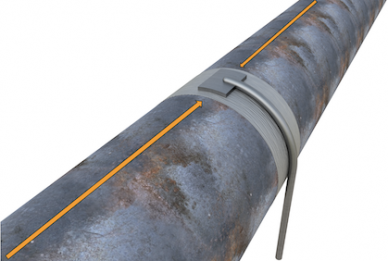

- Place the pad on the cleared surface, checking for fit and aligning the pad with the centerline of the tube facing the flames (Figure 1).

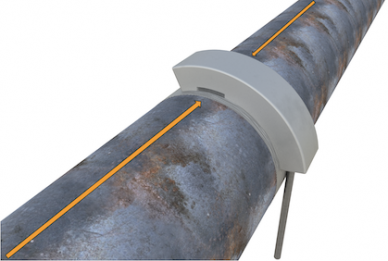

- Place the heat shield over the pad, making sure that the pad fits securely into the shield’s notch (Figure 2).

- Use a chain clamp around the assembly to ensure a flush mount.

-

Weld the assembly on all sides except for where the MI cable exits the pad.

Customized Thermocouple Assemblies for Every Application

We design every Tefracto-Pad® to meet the specific requirements of a furnace, taking into account the tubes’ outside diameter (OD), the optimal thermocouple type and size, the requested connection head, length of the MI cable, sheath materials, and more. This thermocouple assembly is ideal for applications with a temperature range from 32°F to 2,300°F (0°C to 1,260°C). For more information about this easy-to-install tubeskin temperature sensor, contact WIKA USA.

[contact-form-7 id=”14552″ title=”Blog Contact Form”]