At present, a transformation is taking place, with linear drives taking the place of pneumatic and hydraulic drives. Here, there is no longer any scope for measuring pressure. However, WIKA has another solution: Force measurement.

Hydraulic or pneumatic cylinders are increasingly being replaced by electrical propulsion technology. For this, however, it is necessary to implement force measurement using force transducers/force sensors. Force measurement through pressure measurement in a hydraulic unit or pneumatics is not possible. A typical example for this is linear drives.

Force measurement: the initial situation

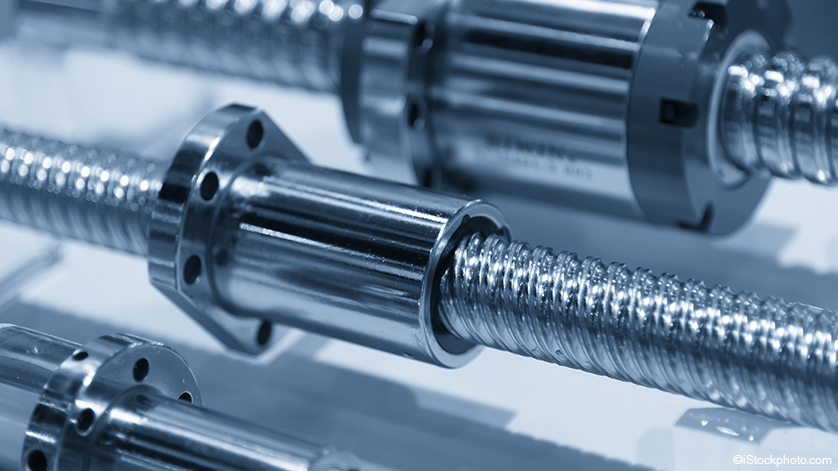

A linear drive is a drive system that leads to a translational movement. Machine elements or system parts are accelerated in a straight line. It makes sense to offer force measurement in such drives, since a transformational change is currently happening: Hydraulically and pneumatically powered drive elements are getting replaced with a combination of electric motor and mechanical thrust units. These modern drive systems are kept simple via modular systems but can, nevertheless, be adapted to individual customer applications with little effort. They also feature a high level of versatility. However, pressure measurement is no longer possible here.

Force measurement: the advantages

This change offers the perfect opportunity to measure forces directly in the process. Force measurement can be used with practically any linear drive. For the precise measurement of the forces, it doesn’t matter where within the force flow the force transducer is integrated. This can be directly on the motor, on the actuator or at the point of force application. Force can be identified reliably at any point in the force flow.

The F2301 force transducers are suitable for force measurement in linear drives

Force measurement: WIKA products in application

For force measurement, thin-film sensors from WIKA’s volume production are used, which are welded onto the measuring tubes of the force transducers. This is also one of the reasons why tecsis, as the force measurement specialist within the group, is renowned for innovative quality solutions in metrology and sensor technology. With the different force transducer solutions, from the standard to the miniature tension and compression force transducers, the optimum solution can be found for every application. This might involve controlling joining forces on electrically powered spindle presses, or monitoring the overload protection in lifting cylinders. The robotic arms of gripping and clamping robots as well as punches, presses and welding tongs can also be measured. With the successful application for the EU “Clean Sky 2” project, the sensors also meet the extremely high safety requirements of the aviation industry.

Note

Our portfolio, our quality standards, our production sites: You can find more detailed information on the subject of force measurement on the WIKA website and in our flyer.