According to UN forecasts, ten billion people will be living on Earth by 2050. The food industry must find new ways to ensure that the growing world population can be fed sustainably. One of these is New Food. This involves biotechnological food ingredients produced from microorganisms, such as proteins. Biomass fermentation is a common process for the production of New Food. It places high demands on the measuring instrumentation.

Biomass fermentation: Efficient production of New Food

Biomass fermentation for New Food enables the production of microorganisms in large quantities and in a comparatively short time. Micro-fungi, algae or yeasts grow quickly and multiply during fermentation to form protein-rich biomass. The resulting ingredient is just as nutritious as conventional protein sources such as meat, fish, eggs and dairy products. In addition, it contains neither cholesterol nor saturated fats.

Every microorganism requires optimum growth conditions in order to thrive as desired. However, other microorganisms can also thrive in such an environment and multiply accordingly. In order to reliably prevent such contamination, aseptic conditions must prevail throughout the biomass fermentation process for New Food. This includes the measuring instrumentation integrated into the fermentation process. Instruments in hygienic design that also guarantee residue-free cleaning are therefore recommended for monitoring tasks in the process.

What are the challenges with biomass fermentation?

Maintaining aseptic conditions, however, is by no means the only pivotal criterion for successful biomass fermentation. The optimum growth conditions must remain constant throughout in order to maximise productivity. Monitoring the critical parameters therefore requires correspondingly high-quality sensing technology. For this task, WIKA has a wide range of instruments in its portfolio.

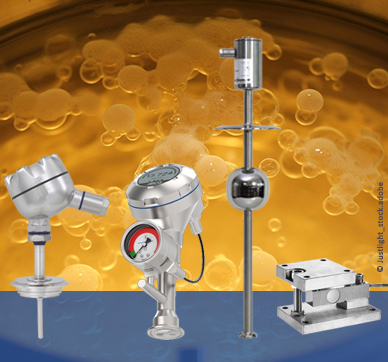

Measurement solutions from WIKA for biomass fermentation for the production of New Food:

Measuring instruments for biomass fermentation for the production of New Food (from left): model TR22-A resistance thermometer, model DMSU21SA pressure transmitter with integrated diaphragm monitoring, model FLM-H magnetostrictive level transmitter and model F3201 shear beam for gravimetric level monitoring (including mounting kit).

- Temperature measurement:

Temperature is the critical measurement parameter during fermentation. This is because the optimal growth and reproduction of microorganisms depends on the continuity of specific temperatures. Any deviation from this can impair the process and therefore productivity. Accuracy is therefore the first selection criterion for the thermometers used for temperature measurement, so that the user can precisely control the heat input. The model TR22-A resistance thermometer in combination with a weld-in thermowell in hygienic design, for example, fulfils this requirement.For processes with high product sensitivity, the TR22-A can also be combined with the T38 temperature transmitter. Its True Drift Detection immediately signals any critical temperature deviation from the sensor. This means that the user can rely on the measured values and does not have to wait until the next calibration interval to detect any drift.

- Pressure monitoring:

Another key measurement parameter for the processes in the fermenter is pressure. It is of primary importance for structural integrity and functioning. This is especially true for large systems. The flush-mounted model DMSU21SA pressure transmitter with integrated diaphragm monitoring can be used for pressure monitoring, for example.This measuring system works with a welded double diaphragm, the space between which is evacuated. If the diaphragm on the process side is damaged, the vacuum is released and the monitoring instrument (pressure switch) emits an alarm signal. The user knows immediately if the aseptic integrity is at risk. The second diaphragm keeps the process securely sealed until the damage has been repaired. This ensures that the measuring instrument poses no danger to the process.

- Level detection:

The fill level in the fermenter is just as important for the fermentation process as pressure and temperature. It influences the mixing, aeration and volume of the culture medium. The method of continuous level detection in turn depends on the condition of the biomass. Float-based measurement is suitable for low-viscosity media, for example with the model FLM-H magnetostrictive level transmitter. The float is designed in such a way that it remains unaffected by foaming and air bubbles. The magnetostrictive measuring principle also provides high accuracy.On the other hand, firmer biomasses in the fermenter favour gravimetric level monitoring, i.e. level monitoring by weighing the vessel and its contents. Load cells, such as the model F3201 shear beam, are recommended for this measurement method without direct product contact. The sensor measures extremely precisely and has high long-term stability. WIKA supplies the measuring instrument plus mounting kit (model AZK02), junction box (model B6578) and display (model E1932) as an assembled and ready-to-install unit.

Regular calibration is essential for precise measuring result

In view of the high demands placed on the measuring instrumentation, regular calibration is essential. Users can test the temperature and pressure measuring instruments directly in the system, for example with the model CTD9350 temperature dry-well calibrator and the model CPH7000 portable process calibrator. In addition, WIKA offers a calibration service with DAkkS certificates, both in the company’s own laboratory and also mobile at the customer.

Note

On the WIKA website you will find further information on the measuring instruments plus accessories mentioned (TR22A, T38, DMSU21SA, FLM-H, F3201, AZK02, B6578, E1932, CTD9350, CPH7000) as well as the calibration service. There you will also find an overview of other measurement solutions for the food industry. If you have any questions, your contact will gladly help you.

Also read our posts

Diaphragm seal system with IO-Link, for the food industry

Pressure switch for safe operation of food silos

Level monitoring in milk tanks using a process transmitter

Pressure monitoring in UHT plant without risk of contamination