The production of biofuels is subject to demanding process conditions. These therefore also pose major challenges for level measurement in biorefineries. The instruments used in the core processes, depending on where they are used, must operate in hydrogen-containing hydrocarbons under high pressure and at the same time in liquids with extremely low densities. WIKA supplied a customer with magnetic level indicators with a special configuration that reliably meet these requirements.

In the quest for a carbon-reduced fuel supply, high-quality HVO (hydrotreated vegetable oil) and HEFA (hydroprocessed esters and fatty acids) play a central role. Both are sustainable products, primarily made from vegetable oils, used cooking oils and also animal fats. They are sold as diesel, but also as aviation fuel.

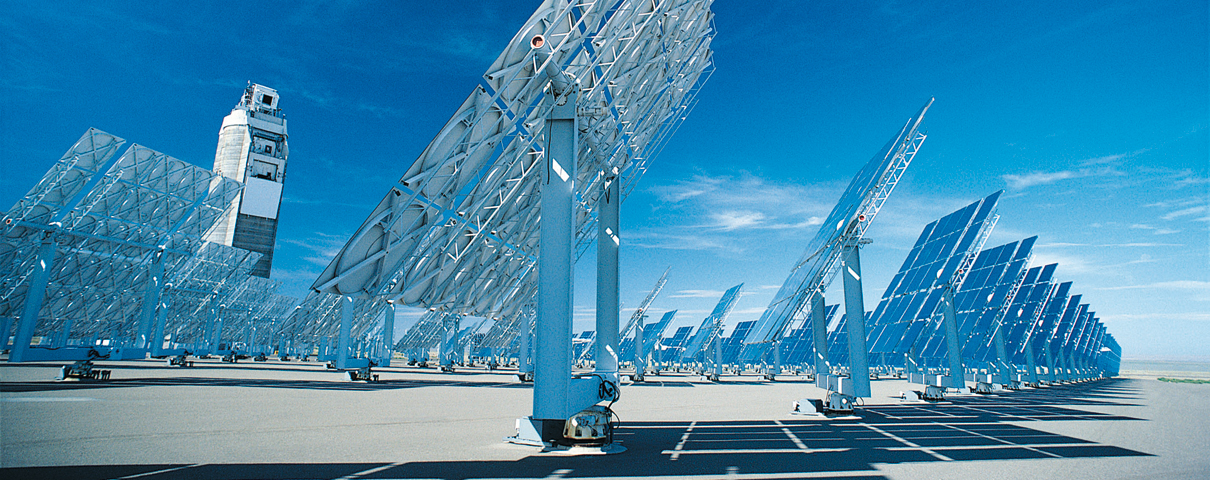

Large numbers of vessels in a biorefinery require precise level measurement

The production of HVO and HEFA involves important production processes, including hydrotreatment and hydroisomerisation. A large number of reactors, tanks and other vessels are used in this process. These fulfil various functions such as catalytic reactions, separation and washing processes as well as regeneration and storage. In all cases, the operators of a biorefinery require precise level measurement.

Reliable level monitoring is difficult to guarantee with standard instruments, especially under the production conditions described at the beginning. The instruments must function reliably in hydrogen-containing hydrocarbons under increased pressures of up to 58 barg and, at the same time, measure precisely in liquids with exceptionally low densities of down to 462 kg/m³.

Titanium floats are pressure-resistant and light enough for low liquid density

The product label indicates the application: In this example, the corresponding model BNA bypass level indicator is designed for liquid biopropane. Depending on the respective process media, model BNA for level measurement in biorefineries – the depicted version features a magnetostrictive sensor and switch contacts – sometimes requires a DLC-coated titanium float (bottom right).

The engineering team at the CoE (Centre of Excellence) Level solved this task with a comprehensive approach and the model BNA bypass level indicator as the basic model. Titanium was selected as the material for the float. This material can withstand high pressures. It is also lightweight, which ensures the buoyancy required for precise measurement – even in the case of a very low liquid density.

Protection through DLC coating

For level measurement in a biorefinery, however, the titanium floats had to be given special protection. This is because there is a risk of hydrogen embrittlement under certain process conditions. For this reason, the floats were coated with a special DLC (diamond-like carbon) coating. This layer forms a strong barrier against hydrogen infiltration and also protects against mechanical damage.

The customer’s technical specifications also necessitated an unconventional, oversized instrument design, which added to the complexity. This required a change from a standard chamber (2-inch, schedule 10) to a more robust 3-inch schedule-40 configuration. Consequently, customer-specific floats with an outer diameter of 72 mm had to be manufactured. This was a challenge that was overcome with innovative technical solutions and precise manufacturing processes.

Special material for the case due to increased risk of corrosion

Special attention was also paid to the case material when designing the BNA. This is because there is an increased risk of corrosion at certain measuring locations due to the potential presence of free fatty acids, carbon dioxide, water and chlorine in the process media. Inconel 625 was therefore chosen as the material for these measuring locations.

Level measurement in the biorefinery – even in the event of a power failure

By integrating advanced materials, precision engineering and customised manufacturing solutions, WIKA delivered magnetic level indicators that meet stringent performance requirements while ensuring long-term reliability in a demanding refinery environment. As the BNA provides a continuous level indication even without a power supply, reliable process control is ensured even in the event of a power failure.

Note

WIKA has also compiled a white paper containing useful information on biofuels and the measuring instruments used for their production. General technical information on the model BNA bypass level indicator is available on the WIKA website. You can also download our brochure “Tailor-made level solutions for the process industry” there. We also present further solutions for the oil and gas market segment. If you have any further questions, please do not hesitate to contact us in person.

Also read our posts

Biofuels and e-fuels as a boost for many engines

Biofuels: Precise temperature profile for production

Using a multipoint thermocouple to produce sustainable aviation fuel

Level limit switches: innovation meets all-rounder

This video also provides information about bypass level indicator