Climate change gives winegrowers a very hard time. Unforeseen weather events such as late frost or heavy rain can cause massive crop losses. The same is true for prolonged drought and moisture. Monitoring environmental conditions is therefore playing an increasingly important role in modern operating practice. For this purpose, industry-proven IIoT technologies can be used in the vineyard as well. This is demonstrated by a temperature monitoring system that WIKA has realised and successfully tested for a vineyard near Klingenberg.

If the winegrower there had lit the anti-frost candles in the vineyard at 4 o’clock on that freezing spring morning as planned, many shoots, and thus the vines of the new vintage, would have fallen victim to the sub-zero temperatures. But the winegrower and his team had already been warming up the air in the vineyard since 2:30 am. “Thanks to the temperature monitoring system, we had been alerted early”, says the winemaker, who was still relieved afterwards.

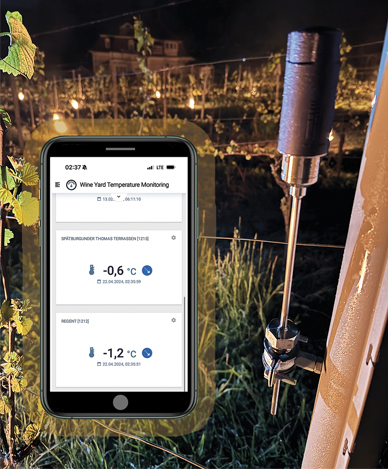

Six battery-operated resistance thermometers are distributed across the vineyard

The model TRW resistance thermometers transmit the measured values from the vineyard every half an hour. One glance at the smartphone gives the winegrower an accurate picture of the temperature development.

The IIoT early warning system set up by WIKA does not fundamentally differ from that of an industrial plant. Six battery-operated model TRW miniature resistance thermometers with wireless transmission are distributed across various plots and locations in the vineyard. Every half hour, the temperature values recorded by the sensors are firstly transmitted via the LoRaWAN® radio standard to a central receiver (“gateway”) and from there bundled and visualised on the browser-based WIKA platform. This enables the winegrower to receive an image of the temperature development at any time via PC, tablet or smartphone and to react immediately if necessary – as in the case of frost.

More than just an alarm function

However, the alarm is only an emergency function. The precise temperature data additionally helps the winegrower to optimise the use of anti-frost candles to contain purchase costs and working times. It can now be determined accurately when, where and in what density the candles are to be lit and when they can be extinguished again. In the case described, the burning time was sufficient for two consecutive frosty nights. Without the monitoring system, all available anti-frost candles would probably have been used up on the first night. This would have meant almost a total loss for this year’s harvest in the vineyard.

However, reacting to acute developments such as frost or the risk of fungal infestation is just one advantage of IIoT-based temperature monitoring in a vineyard; another one is analysing all the data collected in order to identify patterns and trends. It supports long-term planning in winegrowing, for example when selecting the best locations for growing certain grape varieties.

Using IIoT in a vineyard facilitates sustainable management

Through the targeted use of resources and the reduction of damage, the IIoT solution also contributes to sustainability in winegrowing. Wineries can reduce their operating costs and protect the environment at the same time. “A real added value”, says the winegrower who uses the WIKA solution. “Larger companies, in particular, can save resources and therefore a lot of money.”

Note

Find out more about the advantages WIKA offers as an IIoT solution partner on WIKA’s IIoT website. Do you have any further questions about an IIoT system for your application? Then you can directly contact our IIoT team here.

Also read our posts

Hannover Messe 2024: WIKA and the industrial transformation

Pressure measurement: How users benefit from a systems provider

Temperature transmitter T38 doesn’t give drift a chance

Pressure transducer: Digitally connected with EtherCAT®

The following video also provides information on the topic of “WIKA as an IIoT solution partner”