In industrial applications, the corrosion of pressure sensors is a rather negligible phenomenon, since in the majority of applications, oils (in particular hydraulic oils) are used, and contact with the pressure medium is mainly limited to the pressure channel and the …

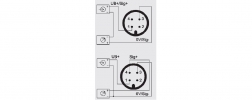

Electrical connection

Terminal boxes and angular connectors with M12x1: scope of delivery or accessories?

Michèle Beyer | GeneralWe are often asked whether for instruments with M12 x 1 connector the corresponding mating connector (also called cable socket or angular connector) is included in the scope of delivery of our pressure sensors. Our clear answer is: no. Unlike the DIN connectors forms A …

Angular connector form A leaking/ loss of IP ingress protection

Michèle Beyer | GeneralWhat are the rules that must be observed when assembling the angular connector EN 175301-803 A, to ensure that the IP rating is maintained, that is, connector and device remain really leak-tight? Unfortunately, a lot of things can go wrong when using the angular …

Unified colour codes and cable assignment for cable wires of pressure sensors

Michèle Beyer | PressureWhy are there no unified colour codes for cable wires of the pressure sensors? This question is entirely justified, because unified wire colours would simplify everything. Not only the manufacturer's different cable versions but also the documentation and installation …

Difference of 4-20 mA in 2-wire and 3-wire technology in pressure sensors

Michèle Beyer | PressureWhat exactly is the difference between the 4-20 mA output signal in 2- and 3-wire technology? This question is answered best from the viewpoint of the user: An output signal in 2-wire technology means: less wiring required better EMC protection, since …