Differential pressure measurement is widely used as a method for monitoring the level of closed vessels. In many cases, operators use individual instruments with an output signal or on-site display. In contrast, a more precise and fault-immune solution is the measuring arrangement developed by WIKA using two process transmitters in a primary-secondary relationship.

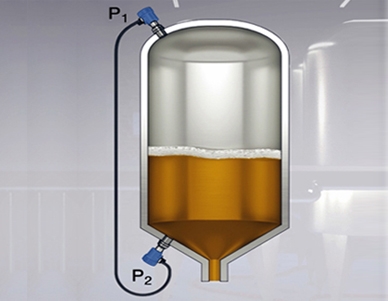

Each level monitoring application using differential pressure measurement is based on the following principle: For the level of the contents in the vessel, the differential pressure between the liquid and the gaseous phase is determined. In addition, the hydrostatic pressure, the specific density of the medium and the vessel geometry are included in the calculation. Typical measuring instruments have two adjacent process connections for the pressures P1 and P2. For level measurement, a capillary has to bridge the pronounced distance between the two measuring points.

Measurement with two process transmitters as Primary instrument (right) and Secondary instrument. This measuring arrangement for level monitoring can be used flexibly, e.g. for information on the mixing ratio of liquids.

Connection via signal cable

When monitoring the level using electronic differential pressure measurement, on the other hand, both measuring points have one process transmitter each. For example, the WIKA models CPT-2x and IPT-2x are suitable for this. The two transmitters are arranged as Primary instrument and Secondary instrument. They are connected, purely electrically, via a signal cable and are therefore not susceptible to disturbances. The Primary instrument supplies the Secondary instrument with power. The Secondary instrument is parameterised via a serial interface or through the display on the Primary instrument. Finally, communication takes place via an internal bus.

Level monitoring in a closed tank

Application example

The figure on the left shows a typical application example for level monitoring with electronic differential pressure measurement on a liquid tank. The Secondary instrument measures the pressure P1, in this case the gas pressure, and transmits it to the Primary instrument. This detects the pressure P2, here the pressure in the liquid column at the bottom of the tank. The Primary instrument calculates the differential pressure from P1 and P2. Using the measured value and taking into account the other parameters mentioned, it determines the volume in the tank as an indication of the level. This value can be output either as an analogue or digital signal to the control room and/or to the display of the Primary instrument.

Advantages of the measuring arrangement with two process transmitters

The method for level monitoring described here has several advantages when compared to a conventional method, for example, with a differential pressure transmitter:

- Higher accuracy and “turndown”

Process transmitters deliver higher levels of accuracy. In the case of the WIKA models, these are up to 0.05 % of the set span. In addition, there is the possibility of “turndown”, the individual setting of a specific measuring span (this is also possible retrospectively with instruments that are already installed.)

- Minimised temperature effect

Transmission via signal cable with electronic differential pressure measurement minimises the temperature effect. In contrast, the capillaries used in the conventional measuring method are much more susceptible here. This, in turn, can ultimately affect the measuring result.

- Fast commissioning

The electronic measuring arrangement can be commissioned faster. Contrary to a solution with capillaries, it does not require any test run.

- Reduced maintenance effort

The maintenance effort is lower: In the event of a fault, only the process transmitter concerned needs to be replaced. In contrast, with measuring differential pressure with capillaries, the complete measuring arrangement must be replaced.

Note

Further information on the model CPT-2x and IPT-2x process transmitters, which are suitable for electronic differential pressure measurement for level monitoring, is available on the WIKA website.