If the careful use of “energy” as a resource used to be for cost reasons, today there is also increased environmental awareness. All of this also becomes mandatory thanks to legal requirements and the state of the technology. In this article you can read about how continuous filter monitoring crucially influences the energy efficiency of a system and supports you in complying with legal requirements.

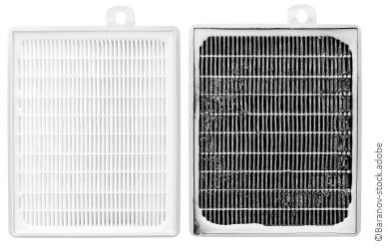

Comparison: New filter – used filter

Whether with air filters in ventilation and air-conditioning systems or oil filters in hydraulic circuits, in both cases, increasing contamination of the filter element causes an increasing pressure drop. In order to keep the flow of the medium (air or oil) constant, the fan or the pump (respectively) must apply more power. The energy consumption increases. Filter monitoring signals the increasing pressure drop across a contaminated filter element. Replacing a fouled filter ensures the flow of the medium and thus prevents the energy consumption of the fan or the pump from increasing.

Legal bases

With the adoption of the Kyoto Protocol in 1997, the European Union committed itself to reducing CO2 emissions. In order to reach this climate goal, in 2005 it adopted the EuP (Energy using Products) directive. In 2009, this was renamed the ErP directive (Energy-related Products directive) – also known as the Ecodesign directive.

Pressure gauge with switch contact, model PGS21

High resistance – high energy consumption

It is easy to understand that a contaminated filter element is more resistant to the flow of a medium than a new, clean element. Physically, the pressure in the inlet (filter inlet) increases – which can be monitored very well using a pressure measuring instrument – and the flow rate is reduced. Since the required flow is specified, more energy must be introduced to compensate for the restriction in the filter.

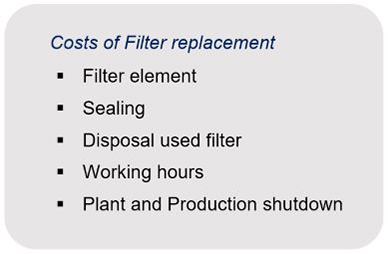

Costs of filter change

Energy-related vs. cost-based considerations

From an energetic point of view, a lightly soiled filter should be replaced straight away. This conflicts with the fact that the exchange itself generates material and labour costs. In addition, the exchange can only take place in the absence of both pressure and flow, and thus the machine or the process must be stopped. Based on these considerations, it is also clear that an exchange after a fixed period of use, as we are familiar with annual services on cars, for example, is not an optimal solution.

Compromise: Filter monitoring

The compromise is an acceptable level of contamination – meaning a specified maximum differential pressure across the filter. Normal limit values for the differential pressure (ΔP) of a hydraulic filter are between 1 and 5 bar. In ventilation systems, the limit values are between 50 to 5,000 Pa (0.5 to 50 mbar). Monitoring the pressure drop saves on operating costs, since changing out the filters only happens when close to reaching the accepted level of contamination of the filter. A further advantage is that, through continuous monitoring, the filter replacement can be scheduled into the operational process.

Filter monitoring through measuring the pressure drop

In each case, the pressure drop across the filter is measured – so ΔP between the filter inlet and outlet. However, the pressure loss across the filter also increases with the volume flow. The ΔP as a indicator of the contamination of the filter may therefore only be assessed in the defined operating state (flow and medium temperature). Filters for liquids can exceed the ΔP limit as a result of brief pressure peaks. Due to inertia, these are not an issue for mechanical switches. For sensors, it is advisable to provide a short dead time in the electronic evaluation (control).

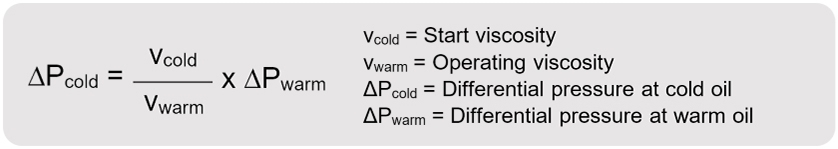

Special case: Filter monitoring in hydraulic circuits

The return filters in a hydraulic circuit are a special case. As the name suggests, these are in the return line, just before the oil flows back into the tank. There is ambient pressure (atmospheric pressure) in the tank. This means that ambient pressure is also present at the filter outlet. This simplifies monitoring, since a differential pressure sensor can now take over the measuring task. This has a favourable effect on the costs of filter monitoring. On the one hand, these pressure sensors are less expensive than differential pressure sensors. On the other hand, you save on needing a pressure line from the filter outlet to the low-pressure connection of the ΔP sensor. Temperature measurement of the oil is essential in hydraulic circuits. This enables the high viscosity of the hydraulic oil, which is still cold when starting, to be taken into account, thus avoiding false alerts. The hydraulic oil temperature is required to control the oil cooler. It has a significant influence on the time over which the oil is used.

Calculation of the excessive differential pressure due to the high viscosity of cold oil

The trend in filter monitoring

Pressure sensor A-1200 with IO-Link

From “preventive maintenance” to “Industry 4.0” to IIoT cloud solutions – there is a demand for data everywhere. This can be seen clearly in the change from traditional measuring instruments with optical displays to electrical sensors with analogue or digital output signals. When monitoring pressure filters, we can see the trend to replace the differential pressure sensor with gauge pressure sensors before and after the filter. This gives one both the system pressure and the pressure at the outlet of the filter, which a differential pressure sensor does not offer. The pressure drop, the difference between the two signals, is then calculated in the electronic control, in the edge computer or in the cloud.

Note

In addition to pressure sensors for filter monitoring, the WIKA portfolio covers all relevant measurement parameters that are necessary for controlling and regulating the operating states of a machine or system. Further application examples can be found on our website in the “Industries” section.

Also read our article

Safe filter monitoring with differential pressure gauges