Gasification reactors, due to their harsh process conditions, place high demands on the instruments used there. Many manufacturers have reacted to this and adapted their products correspondingly. But what are the optimisation possibilities for thermocouples for use at higher process pressures?

The challenge: “Gasification reactors”

In a gasification reactor, there is an extremely aggressive process atmosphere and, with that, the risk of poisoning of the noble metal thermocouple. The process conditions often lead to shutdowns and interruptions in operation. Profitability and safety aspects are thus two important themes in connection with the instruments used in them.

WIKA sapphire-design thermocouple TC84

Method of resolution: Sapphire thermocouple

Through the use of a sapphire protection tube, the high-temperature thermocouple is protected from poisoning by the aggressive process atmosphere during operation. The reason for this is its monocrystalline structure. The sapphire-design thermocouple has, as a result of its construction, a significantly higher service life than other high-pressure thermocouples and, therefore, contributes to a clear reduction in the process downtime.

Advantages of a sapphire thermocouple

- 3 times longer service life in comparison to purely ceramic thermowells due to the monocrystalline structure of the sapphire thermowell

- High process safety with processes up to 1,700 °C and 65 bar

- Cost saving due to the elimination of complex purge systems and valves and fittings for flow measurement

- Reduction of unplanned downtime

- Increased safety against escape of toxic media through double sealing system

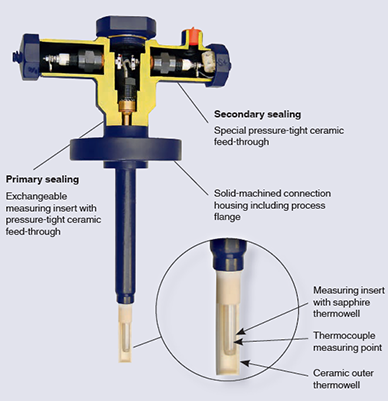

Construction of the TC84 sapphire-design thermocouple

Special construction of a sapphire thermocouple

The special construction of a sapphire thermocouple provides increased safety.

- The primary sealing serves as protection against the escape of toxic process gases at high pressures and also at high temperatures

- The secondary sealing is the safeguard in the event of a malfunction in the primary seal due to any unforeseeable disturbance to the primary seal

- The ceramic outer thermowell serves as protection against harsh process conditions

- The sapphire protection tube protects internally against contamination of the thermocouples through diffusion

Note

WIKA has developed the TC84 sapphire-design, high-temperature thermocouple specifically for use in gasification reactors. Further information on the TC84 can be found on the WIKA website and in our flyer.