For plant operators a permanent temperature sensor’s drift tends to be a pain in the neck. This defect usually becomes apparent at a following calibration – in other words: too late! Until then it might have caused a false temperature measurement and compromised the process in the end.

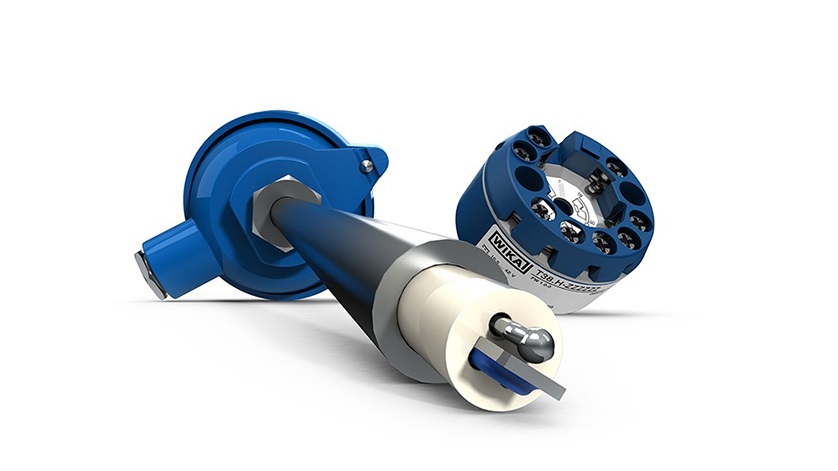

WIKA’s newly developed temperature transmitter T38 now enables the user to prevent this kind of defect from happening. Its prominent feature is the unique True Drift Detection (TDD). Connected with a specific WIKA thermometer, it continuously monitors the complete measuring range for critical deviation. The technology works for measuring ranges from -50 °C up to +500 °C. This combination provides a comprehensive self-monitoring of the sensor, making it fit perfectly into digitalised processes.

True Drift Detection: Demand-driven interventions instead of fixed recurring checks

Resistance thermometers are widely used to monitor process temperatures. Although generally robust, a persistent above-average stress causes the sensor to drift, induced for instance by high temperatures, heavy temperature fluctuations or humidity. While processing the sensor signal, the read-out unit of temperature transmitter T38 will immediately detect any critical deviation of the resistance characteristic. It has implemented a smart algorithm in order to check and compare the values measured by the matched sensor and the reference element. The defect is then reported via HART® communication protocol or on the current loop.

The plant operator is able to react in due time. Such condition monitoring leads to immediate, demand-driven interventions. Otherwise, a drift would not be detected until the next recurring check based on a defined maintenance plan. Thus, TDD makes processes more reliable and safer.

Probe with integrated reference: Easy upgrade of measuring locations

For TDD, the temperature transmitter has to be combined with an appropriate WIKA thermometer. The probe design is based on the proven temperature measurement principle with a platinum resistor (RTD) in accordance with IEC/EN 60751. The reference element is installed parallel to the RTD in the probe tip and perfectly matched for optimal measuring and monitoring results. The sensor has a resistance characteristic conforming to the standard, and the instrument always indicates the currently measured value. The reference element and its signal are prevented from averaging or distorting the measured value by the underlying concept of the TDD technology. Since the probe has identical geometry to conventional solutions, existing measuring locations can be upgraded easily.

Temperature transmitter T38: Distinct versatility and uncomplicated installation

The temperature transmitter T38 offers distinct versatility for all branches of the process industry. It’s available as head or rail-mounted version. The head version can also be supplemented with a clip-on display for on-site readout. Besides the TDD thermometer, the transmitter supports all common sensor types, which can be connected and measured as single or dual sensors. A wide choice of measuring ranges is provided accordingly.

The upshot for users is a temperature measuring system tailor-made for their particular application, which is ready to use straight away. It can be integrated into the process according to the plug-and-play principle. Any altering of configuration can be easily and flawlessly accomplished via HART® protocol.

T38 with SIL 2 and new Ex d field housing: Solution for use in hazardous areas

Concerning safety applications, the temperature transmitter T38 is first class. Both instrument models have SIL 2 certification in accordance with IEC 61508 and are approved for use in hazardous areas. A mineral-insulated metal-sheathed cable, which was specially developed for True Drift Detection, supports the resilience of the entire thermometer. Furthermore, the transmitter can be combined with the new Ex d field housing, model PIH/PIR, showing a distinct resistance to extreme temperatures, humidity, mechanical stress and the effects of salt water.

Another safety feature is added by the special trapezoidal terminal design of the head-mounted version of the T38. Its very large clamping area and an access from the outside enables error-free connection of both the probe and the current loop.

Conclusion

WIKA’s T38 marks a new generation of temperature transmitters, supporting plant operators to increase the efficiency and safety of their processes. It offers:

- Comprehensive condition monitoring due to the True Drift Detection over a measuring range from -50 °C to +500 °C

- Suitability for all branches of the process industry, especially for safety applications and digitalised processes

- Easy and error-free installation, including the upgrade of existing measuring locations

Note

For more and detailed information about the temperature transmitter T38, please have a look on the WIKA website. There you will also find an overview of other measurement solutions for the process industry. Should you have any further questions, your contact will gladly help you.

Also read our posts

Ice cold – Electrical thermometers in low ambient temperatures

Application of sapphire thermocouples in gasification reactors

Measuring the response times of electrical thermometers

Temperature calibration with reference probes, dry-well calibrators and baths