Thermocouples are hardworking temperature sensors found in many industrial applications. Find out what thermocouples are, how they work, and why they are so popular.

Thermocouples are electrical devices used to measure temperature. Their accuracy, rapid reaction time, and ability to withstand heavy vibrations, high pressure, and extreme temperatures make them ideal for a wide range of applications. But how does a thermocouple work?

Thermocouple Working Principle

The working principle of a thermocouple follows the Seebeck effect, or thermoelectric effect, which refers to the process in which thermal energy is converted into electrical energy. The effect describes the electrical voltage that occurs when two different conductors are connected, and how the voltage produced varies with temperature.

The basic design of a thermocouple involves two dissimilar metal wires, each with different electrical properties at different temperatures. The two metals are in contact – touching, twisted, or welded – at one end; this is the measuring point. At the other end is the connection point, so called because it connects to the voltage reader. When the temperature changes at the measuring point, so does the electron density of each metal wire. This varying electron density is the voltage, which is measured at the connection point.

Note that thermocouples do not actually measure the absolute temperature. Instead, they measure the differential temperature between the measuring point and the connection point. That’s why thermocouples also need a cold junction compensation, which ensures that the ambient temperature at the connection terminals of the cold junction does not alter the measuring result, thus allowing for more accurate readings.

Metal Pairings in Thermocouples

For a thermocouple to work well, its two wires should offer as much contrast as possible in individual electronegativities. This is so that the voltage reader can detect the greatest thermoelectric voltage difference.

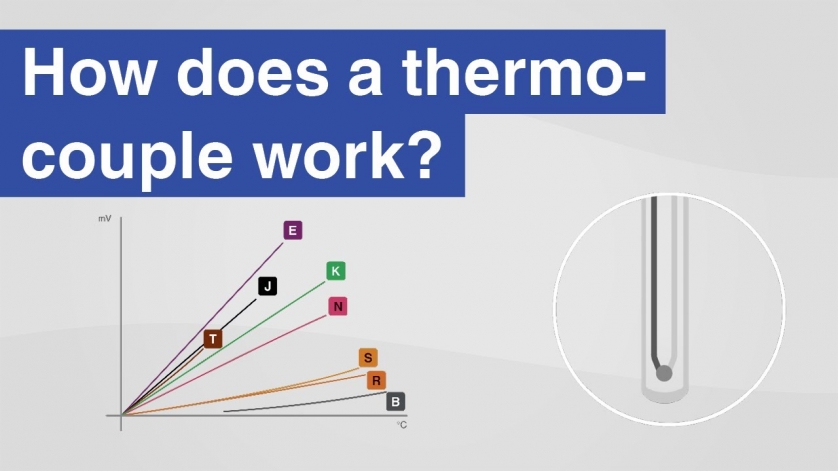

Base metal thermocouples, known as Types J, T, K, E, and N, produce higher thermoelectric voltages than more expensive noble metals, known as Types R, S, and B. The latter type, however, can withstand temperatures up to 3,092°F (1,700°C).

See this table for more information about the operating temperature ranges for each type of thermocouple, please refer to the table below.

Thermocouple Type | Temperature Range |

Type J | −40…1,400°F (−40…760°C) |

Type T | −328…698°F (−200…370°C) |

Type K | −40…2,300°F (−40…1,260°C) |

Type E | −40…1,652°F (−40…900°C) |

Type N | −40…2,300°F (−40…1,260°C) |

Type R | 32…2,912°F (0…1,600°C) |

Type S | 32…2,912°F (0…1,600°C) |

Type B | 1112…3,092°F (600…1,700°C) |

WIKA USA manufactures a comprehensive range of high-quality thermocouples with various temperature ranges, configurations, and materials. For more information about how a thermocouple works, watch this short video or contact our temperature measurement experts.

For more information, contact WIKA USA.

Great post! I specifically like how you clearly explained Base metal thermocouples – not a lot of people have a full understanding of what these are, nor their classifications.