After a contamination incident caused by a diaphragm seal failure, a m ajor U.S. pharmaceutical company switched to WIKA’s reliable Diaphragm Monitoring System to avoid another costly and time-consuming shutdown. Today, as the nation eagerly awaits a treatment …

case study

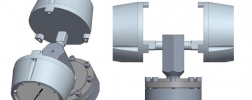

Case Study: Unique Diaphragm Seal Assembly Meets Customer’s Precise Requirements

Chi-Che Ma | PressureA company in the energy and water/wastewater sector contacted WIKA about installing a diaphragm seal on a pipeline with limited clearance, but with a specific stipulation: The process gauge had to be readable from both sides. WIKA’s Diaphragm Seal Division designed a …

Case Study: Why a Major Agricultural Machinery Company Started Using WIKA’s Level Sensors

Jeff Placek | Applications, LevelA U.S. manufacturer of agricultural equipment has long relied on WIKA’s pressure sensors for machine control. It now is starting to use the RLT-1000 in its sprayer tanks, a critical area for level measurement in farm sprayers, due to this level sensor’s quality, …

Case Study: Increasing Thermocouple Lifespan in Reactor with WIKA’s Field Service

Robert Torgerson | ApplicationsA leading manufacturer of consumer and industrial chemicals experienced difficulties during regular turnarounds of their tubesheet reactors: The multipoint thermocouples used to measure reaction temperatures were found to be damaged after every operation. With the help …

A Supplier Development Partnership Maximizes Value, Drives Innovation

Patrick McGrath | ApplicationsWhether you work with industrial gases or manufacture components for mobile working machines, you deserve more from your instrument supplier than just off-the-shelf technology. You need a supplier development partnership with a company that has a deep knowledge base …