As a globally active company, WIKA strives for sustainability worldwide. All locations contribute to this at different levels. Environmental protection, climate protection, the support for people within as well as outside the company and the concurrent pursuit of corporate objectives all go hand in hand. Many initiatives that have been implemented are already making a positive contribution towards the achievement of WIKA’s sustainability objectives. This is demonstrated by the following examples:

Energy saving at WIKA Italy

On the road to achieving global sustainability, every step counts, even if it seems small at first glance. For example, by equipping our production facilities in Italy with LED lighting, we have been able to achieve a 55 percent saving in energy consumption. While the installed rating before the replacement was 8,400 watts, it was only 3,780 watts afterwards.

WIKA South Africa supports school-age children

Ever since 2013, WIKA South Africa has been involved in helping the informal settlement of Mangolongolo. The subsidiary has initiated a nutrition programme there. It also helps school-age children by buying school shoes, bags, uniforms and stationery. A child care facility for children aged three to six has also been set up within this community. The provision of aid also extends to other residents of the settlement.

Another initiative of the subsidiary created a fruit and vegetable garden for the children of the “Denver Primary School” in Johannesburg and the “Centre for Early Childhood Development” in Cape Town. Many of the girls and boys come from neighbouring informal settlements. The garden helps to enrich their daily menu, provide monthly food parcels and generate additional income (photo above). This income goes towards school materials and uniforms for the children, for example.

Global sustainability through wastewater project in Indonesia

Global sustainability also means that people in Indonesia receive safe wastewater disposal with the help of WIKA.

WIKA MENAT, the subsidiary in Dubai, is helping to improve wastewater disposal in Indonesia. In the island state, many people die from contaminated water, especially children. This also applies to families living on pile dwellings who are forced to discharge wastewater and solid waste directly into the sea.

The NGO “Safe Water Gardens (SWG)” has developed a new system for safe wastewater disposal especially for these people, the so-called wet SWGs. They consist of a wastewater tank and a piping system connected to the toilet and a sink. The big advantage is that these SWGs, like the others, are also maintenance-free.

Financial support from WIKA MENAT has made it possible to install the first ten of these systems on the island of Riau. For the first time, ten families now have sanitation facilities. The island government is enthusiastic about the SWGs because they are better and, at 200 euros, many times cheaper than previous systems. WIKA MENAT is proud to have made this project possible.

Subsidiary in India works with packaging material made from cellulose

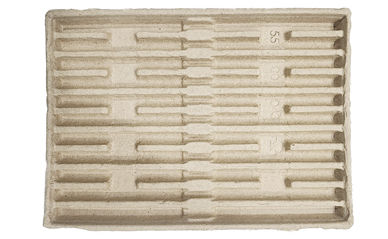

Sustainable packaging material of WIKA India

WIKA India has fundamentally modified the packaging process for bimetal modules at its Ghaziabad site, located east of the Indian Capital New Delhi. Instead of expanded polystyrene (EPS), the subsidiary now uses cellulose-based materials. In addition, it has introduced cellulose shells for Hallwa and AFCG products. This environmentally friendly packaging is made from paper pulp.

Recycled brown cardboard is used as the base material. Only one mould is now needed to produce packaging for five product variants. This innovation will also be used for other product lines in the future.

Reduction of water consumption in the production of force measurement technology

Laser systems in the production of force measurement technology now have a closed cooling system, which significantly reduces water consumption at the tecsis site.

The German tecsis site in Offenbach am Main supports WIKA’s global sustainability with an alternative cooling system for the laser systems used in production. The systems were supplied with municipal water for years, which ultimately meant wasting a valuable resource. Following a suggestion from an employee, the site gradually upgraded the laser systems to a modern, closed cooling system.

By reducing water consumption, the site improved its resource efficiency and reduced negative environmental impacts. The changeover to the new cooling system reduced the site’s annual water consumption by around 2,000 cubic metres, which corresponds to a saving of around 85 percent per year.

Note

Further information on WIKA’s sustainability strategy can be found on the WIKA website.

Also read our posts

Climate protection: WIKA promotes e-mobility and job bike

Honoured for energy saving: Micro Precision Products

Green hydrogen: WIKA Chile impressed the audience