A hydrostatic pressure test is used as a proof of strength and leak tightness of containers and pipelines that hold liquids and gases. The procedure and documentation of such a test can be increased in efficiency by using digital pressure gauges. This is particularly the case if the instruments have a wireless interface for data transmission, e.g. Bluetooth®.

KSR KUEBLER, the WIKA Group’s “Center of Excellence” (CoE) for level measurement, manufactures bypass level indicators and external chambers, among other things. Their level chambers as well as the floats of the level indicators are pressurised components. They must, therefore, be subjected to a hydrostatic pressure test. The test is passed if no pressure loss occurs during the defined test time. It is a fixed part of the acceptance test and the related protocol also serves as proof of operational safety.

Considering the high daily quantity, the CoE level measurement has to take into account a considerable amount of time for the hydrostatic pressure test. Each test item is subjected to a constant component-specific pressure for 15 and 30 minutes. The test medium is water.

Hydrostatic pressure tests in production require mobile equipment

The hydrostatic pressure test takes place in the flexible production lines as the final production step. That is why it requires mobile equipment consisting of a pressure generation unit for the test pressure as well as a measuring instrument. In the past, the CoE had to conduct the hydrostatic pressure test with five pressure gauges with different pressure increments per test setup to cover all required scale ranges. Subsequently, it used a model CPH6200 hand-held by WIKA with an external reference sensor, which significantly streamlined the test process and made it safer. The hand-held had a higher accuracy and made the documentation easier through data transmission to an end device via USB interface. Additionally, the recalibration effort was reduced to just one reference instrument.

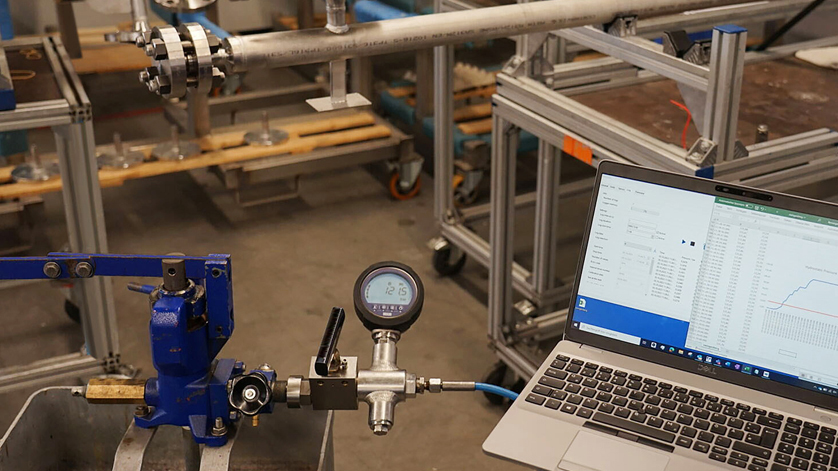

The display of the digital pressure gauge can be read clearly

Nevertheless, the CoE aspired to increase efficiency and continue to reduce manual operations. The consequence of this was the change from the hand-held to the model CPG1200 digital pressure gauge by WIKA. The test instrument is now permanently installed on the pressure generation unit. It has a large display with backlighting that ensures clear readability even in poor lighting conditions. Thanks to the measured value display with two to three decimal digits, the operating personnel can also recognise at a glance whether the test pressure remains constant or whether a pressure loss indicates a leakage.

If higher accuracies than 0.25 % FS are required for a pressure test, there is the precision instrument CPG1500 with an accuracy of up to 0.025 % FS and a display with up to four decimal digits. Both the CPG1200 and CPG1500 are also able to measure temperature. Knowledge of the temperature profile and its possible effects on pressure measurement is particularly important for reliable results of tests over a longer period of time.

Optimal documentation thanks to wireless data transmission

The key advantage of instrumentation with both WIKA digital pressure gauges, however, is the optimised documentation. The instruments are equipped with a powerful data logger and a Bluetooth® interface. They provide a documentation of the test sequence without gaps – both numerically and graphically. Using the WIKA-Cal software, all data can be immediately transmitted wirelessly to a notebook for further processing for the test report.

Note

On the WIKA website you will find technical details about the model CPG1200 digital pressure gauge and the model CPG1500 precision digital pressure gauge, which can also be ordered in our online shop. You will also find further information about pressure tests on the website. If you have any questions, your contact will gladly help you.

Also read our posts

Advantages of in-situ calibration using the example of pressure switches

Pressure monitoring for mobile tanks in pharmaceutical processes

Calibration with portable instruments in hazardous areas

Mobile calibration service