Determining the weight of a mass requires a so-called load cell. Load cells are a special form of force transducer used to determine the weight force. This means that load cells are typically calibrated in weight units such as grams, kilograms or tonnes instead of the usual newtons or kilonewtons used for force transducers.

Just as force transducers measure the forces acting on them, load cells measure the weight that acts on them through the weight force. In both cases, the acting force deforms the sensor elastically, leading to a linearly proportional change in the output signal. Every force transducer and load cell is therefore a measuring body that returns to its original state after loading.

The right load cell, the right accessories

Weighing technology

Every application has a specific measuring body geometry that is best suited to it. The relevant factors are the measurement accuracy, the material used (and the associated costs), the weight to be measured including possible overload as well as the number of load cells required.

Depending on the place of use, force introduction components may be necessary. In some applications, the load cells can be installed directly, for example if holding fixtures are already attached to a vessel; in others, weighing modules are required, for example if a vessel stands directly on the ground.

Even though an additional weighing module means additional expenses, it also offers a number of advantages, such as the prevention a force shunt (i.e. incorrect measuring results) and built-in mechanical overload protection. In addition, thermal expansion and vibrations are compensated and the entire assembly is earthed via a sufficiently thick cable.

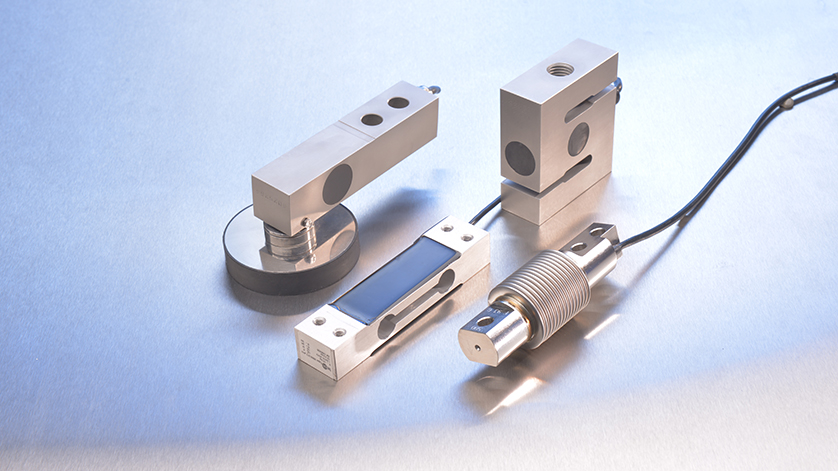

The different types of load cells

But back to the actual measuring bodies, the load cells. There are many different designs, which could hardly be more diverse regarding their form:

-

Single point load cells

Probably the most common load cell is the so-called single point load cell. In appearance, it resembles a cuboid with a cut-out in the shape of a dog bone. On both sides, there are holes and threads provided for mounting. As they are mounted between two platforms or plates, they are sometimes also called platform load cells. The special feature is that it does not matter where the weight to be determined is positioned on the upper platform – the measurement is always correct. Single point load cells are typically used in all types of platform scales (bathroom scales, supermarket scales, etc.) and are suitable for light weights of up to around 600 kg.

-

Bending and shear beams

Bending beams and shear beams are also widely used. These load cells are basically (stainless) steel beams that are deformed by the weight to be measured. Again, the name reveals their function, with bending beams being bent and shear beams being sheared. Bending and shear beams are typically mounted under vessels – usually with a weighing module – and are suitable for weights of up to 500 kg (bending beam) or 10 t (shear beam).

-

Compression or canister load cells

For larger vessels, compression load cells or canister load cells are usually used. They look like discs or cylinders that have protrusions with a smaller diameter on one or both sides. These protrusions are used for targeted force introduction. Compression or canister load cells are also typically used for vessel weighing – for silos or vessels that become very heavy. These load cells have measuring ranges of up to 300 t. The use of weighing modules is therefore essential.

-

S-type load cells

The so-called s-type load cells are also very widely used. In this case, the name describes their shape, as they look like an angular letter “S”. The ends of the “S” can be designed as an overload protection. S-type load cells are characterised by their compact design and high accuracies. They are often used to weigh suspended vessels. They are also used in many different (material) testing machines.

-

Planar beam load cells

Finally, planar beam load cells should also be mentioned. The name comes from their flat design, which makes them perfect for use in kitchen scales or hospital beds.

-

Special designs

There are several more, but it would be pointless to list them all. In general, load cells are characterised by a very high measurement accuracy. When deciding on the right design, you can weigh up various options.

Note

In its portfolio, WIKA has the right solution for every application. If you have any questions, your contact will gladly help you. Further information on our product range for weighing technology can be found on the WIKA website.

Also read our posts

How to build scales