Diaphragm pressure gauges are genuine multi-purpose instruments. For example, in processes with critical media, they enable comprehensive possibilities for reliable pressure measurement with long-term stability.

Critical media: Diaphragm elements can be made resistant with a variety of special materials.

Aggressive media

Processes with aggressive media require measuring instruments with wetted parts made of corrosion-resistant material. In a diaphragm pressure gauge, this requirement primarily relates to the pressure element. For the resistance of the diaphragm element, a wide range of special materials can be used, from PTFE to tantalum, Hastelloy and titanium to gold. For comparison: For a Bourdon tube, usually only stainless steel and Monel are considered.

In addition to the resistance, the special material must also meet the elasticity and sealing required for the measuring task. The diaphragm of the diaphragm pressure gauge is usually glued with a foil of the selected material or, in the case of gold and platinum coating, it is galvanised. In some cases, the diaphragm element is even made entirely from the special material.

For applications with particularly aggressive media, the lower flange of the diaphragm can also be lined with the special material. The wetted area of the measuring instrument is then completely protected.

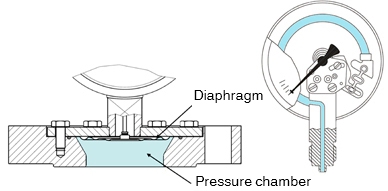

Diaphragm pressure gauge with open connecting flange (l.): In the large pressure chamber, no media can settle. Due to the narrowness of the Bourdon tube (r.), there is a risk of this.

Viscous and similar media

Diaphragm pressure gauges are also suitable for measuring tasks with viscous, crystallising and contaminated media. Such media can clog the narrow pressure ports in a threaded connection and even the interior of the tube with Bourdon tube pressure gauges. Diaphragm pressure gauges with an open connecting flange in accordance with EN 1092-1 or ASME B 16.5 (preferred nominal widths DN 25 and 50 or DN 1″ and 2″) eliminate such troubles. This form of process connection creates a large pressure chamber in which no media can settle.

Sensitive media

Diaphragm pressure gauges are also suitable for sensitive media in the food and pharmaceutical industry: in a design with flush diaphragm. For a dead-space-free connection, the pressure element is welded directly to the hygienic process connection. Another advantage is the principle of operation which uses a dry measuring cell: The pressure is transmitted without transmission fluid which could otherwise contaminate the medium in the event of a fault.

Note:

Further information can be found on the WIKA website under the headings Pressure gauges and Pressure gauges with output signal.

See also our articles:

Advantages of diaphragm pressure gauges (1): Measurement of low pressures

Advantages of diaphragm pressure gauges (2): High overload protection

Pressure gauges for pharmaceutical processes: Flush-mounted “dry measurement”