Time settings can be made for each electronic pressure switch. Through these, users clean the measurement of the pressure profile in the application and the display of the measured value of any insignificant “outliers”. As a result, you receive a smoothed result for the pressure measurement. There are two types of time setting.

1. Delay times

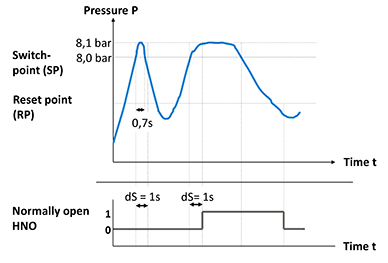

Fig. 1: This is how a pressure switch with a set delay time reacts to a pressure profile.

Delay times can be set independently of one another for all switching and reset points. They are used to “filter out” short-term pressure changes. In order for an electrical signal change to occur at the switching output, the pressure must be present at the switching or reset point for this time, and without interruption. An example: An electronic pressure switch should signal to the control unit when the operating pressure of 8 bar has been exceeded. In this case, the switching delay time is 1 s. The pressure exceeds the switching point and rises to 8.1 bar. After 0.7 s the pressure drops again and then remains below 8 bar. Due to the specified delay time, the pressure switch does not react to the change in pressure and there is therefore no signal change at the switching output. That step would only occur if the pressure were still at 8.1 bar after 1 s had elapsed.

2. Damping times

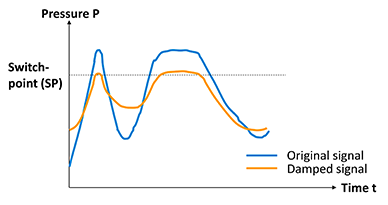

Fig. 2: Concept of damping time in general (principle sketch).

The second of the time settings on a pressure switch is the damping time. It can be set independently for the digital display, the switching outputs and the analogue output. The damping time causes the measured values to be averaged before they are displayed. In the case of rapidly fluctuating pressure, for example, the measured value shown on the display can be stabilised and any analogue signal can be smoothed out.

On the one hand, this ensures that measured values can be read more easily. On the other hand, the damping time prevents the control from reacting immediately to all fluctuations. Any delay times for switching outputs can also be combined with this. This can be necessary, for example, with pneumatic systems. This is because, compressed air cylinders with different piston diameters and strokes cause the pressure to fluctuate during forward and backward strokes. This behaviour is typical for normal operation. It therefore requires no intervention by the controller.

Time settings on the PSD-4 pressure switch

In which spans are time settings possible with a pressure switch? The PSD-4 from WIKA, for example, enables a margin of up to 65.00 s in both cases. The user can set the delay time in increments of 50 ms and the damping time in increments of 100 ms. The only factory preset is the damping time for the digital display (0.20 s).

Note

Further information on electronic pressure switches can be found on the WIKA website. If you have any questions, your contact will gladly help you.

Also read our posts

Electronic pressure switches: Many setting options

Switch points in vacuum ranges: How are they set?

What is meant by the switching function “hysteresis” with electronic pressure switches?

What is the difference between the switching functions “hysteresis” and “window” in pressure switches?

What is meant by the “normally open” switching function with pressure switches?