By using thermocouple sensors and plotting temperature measurements at different points in the catalyst bed, syngas plant operators can accurately predict catalyst behavior. The resulting “S” curves – along with shifts and shape changes over time – also give …

All posts by Robert Torgerson

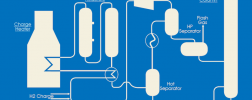

WIKA’s New and Easy Way to Find the Right Measuring Instrumentation for Hydrocracking Processes

Robert Torgerson | ApplicationsAn interactive pipeline and instrumentation diagram (P&ID) by WIKA USA simplifies the evaluation and selection process for the best temperature, pressure, and level measuring solutions for your hydroprocessing applications. A couple of clicks on the diagram …

Prevent Hydrocracking Runaways with the Gayesco Flex-R® Multipoint Thermocouple

Robert Torgerson | TemperatureThermal runaways in hydrocracking processes are a serious concern for refiners. Comprehensive, real-time temperature monitoring is critical to preventing runaways, which is why most hydrocrackers across the world are equipped with Gayesco Flex-R ® multipoint …

Temperature Measurement: An Effective Tool for Monitoring Catalyst Performance

Robert Torgerson | Know-howRefineries rely on accurate temperature measurement and monitoring for information about catalyst performance and remaining catalyst life. The key measurements in a syngas (synthesis gas) shift reactor are 1) approach to equilibrium temperatures and 2) exotherm …

Accuracy and Response Times for Thermocouples, Thermowells and Other Temperature Instruments for Syngas Plants

Robert Torgerson | Know-howEach temperature measurement system on the market has its particular features and limitations. When deciding which ones to use in syngas plant reactors, it is important to take into account the response times, accuracy, and other specifications of thermocouples, …