WIKA is a global company with decades of instrumentation experience, including a deep understanding of alloys and different manufacturers’ trade names for them. That’s why EPC companies from around the world partner with WIKA on offshore and seaside engineering …

oil and gas

WIKA Diaphragm Seal Repair Service: Exceeding Customer Expectations

Chi-Che Ma | PressureWIKA USA Diaphragm Seal Division, formerly RJ Global, offers diaphragm seals that save customers significant time and money. Instead of replacing an entire process transmitter, send the damaged diaphragm seal assembly - regardless of the fire - to the Houston-based …

Extreme Cold Calls for Reliable Low-Temperature Resistance Thermometer

Gabriel Gonzales | TemperatureThe majority of new oil and gas fields are concentrated in Siberia and northern Canada. The increase in extraction activity in these regions, along with the need to process the oil and gas locally, has resulted in a growing demand for temperature measurement solutions …

Liquid-Filled Pressure Gauge for Extremely Low Ambient Temperatures

Hardy Orzikowski | PressureMost pressure gauges work in ambient temperatures as low as − 40°F ( − 40°C). However, around the Arctic Circle, the norm is below − 40°F, which is too extreme for conventional pressure gauges to handle. Model PG23LT from WIKA is a high-performance …

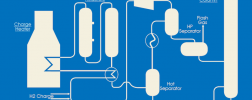

WIKA’s New and Easy Way to Find the Right Measuring Instrumentation for Hydrocracking Processes

Robert Torgerson | ApplicationsAn interactive pipeline and instrumentation diagram (P&ID) by WIKA USA simplifies the evaluation and selection process for the best temperature, pressure, and level measuring solutions for your hydroprocessing applications. A couple of clicks on the diagram …