Operators of district heating networks face various challenges. In view of the shortage of skilled labour, new legal requirements and demanding end customers, it is important to make the operation and maintenance of networks as reliable and efficient as possible. IIoT solutions for digital remote monitoring of district heating networks have a key role to play here.

Planning, diverting traffic, opening manholes, going down them, securing – the maintenance of district heating networks involves a lot of manual work. Recording a single pressure value alone requires detailed planning: Which measuring locations need to be reached? Is the measuring location under a busy road? Which employee is deployed where? Are there any critical sections?

On the day of the maintenance work, a technician visits the measuring location. As a large part of the district heating network runs underground, access often leads through a narrow maintenance shaft. To minimise the risk of injury to staff and passers-by, security must be provided by a second employee.

Once at the measuring location, the technician reads the current measured value and documents it manually. In the best case scenario, the system is in the intended state. Furthermore, the network operator is left with a number of questions about which the current measured value provides no information:

- What was the pressure yesterday, what will it be tomorrow?

- What measures are necessary if a drop in pressure has been registered?

- Did the pressure drop quickly or over a longer period of time?

Condition monitoring of steel casing pipes reduces energy losses

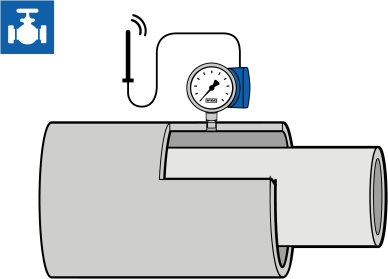

Steel casing pipe with an IIoT-capable WIKA PGW23 pressure gauge in combination with a detachable antenna. This design enables good transmission ranges of several kilometres and is also suitable for demanding installation conditions such as in maintenance shafts.

Identifying pressure drops quickly is essential for efficient operation of the district heating network. A lack of system transparency, on the other hand, can result in high costs. This becomes clear, for example, when monitoring the annular-space pressure. Double-walled pipes consist of an inner carrier pipe and an outer casing pipe. There is a vacuum between the pipes for insulation. Over time, air penetrates from the outside so that the insulation effect can be reduced to as much as a tenth of the initial value. This results in high heat losses, the efficiency of the overall network decreases and costs increase.

Digitalising district heating networks with IIoT: Standards and wireless transmission

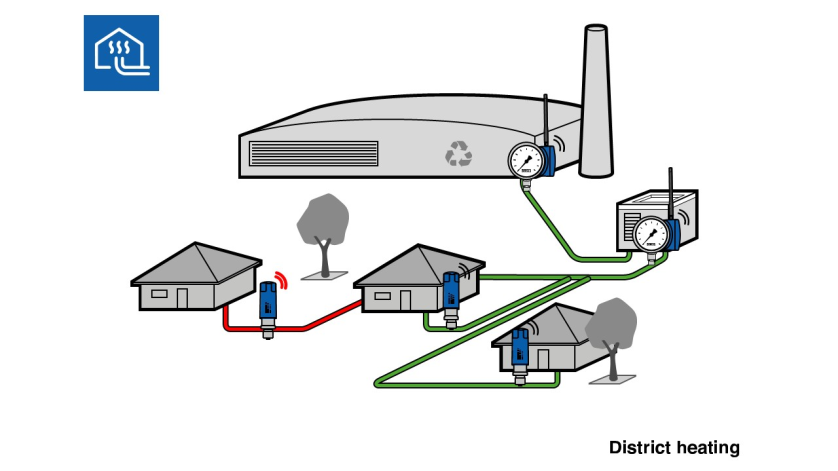

Pressure drops can only be recognised at an early stage through remote monitoring of the measuring locations. In the past, implementation was time-consuming as network operators had to wire each individual measuring location. With modern IIoT solutions, installation is now much easier. Battery-powered IIoT instruments, and data transmission via the LoRaWAN® and mioty® wireless standards, make it possible to network the measuring locations digitally with minimal time and cost.

WIKA covers the entire chain from the measured value to the platform and integration. All measuring locations can be easily visualised on a central, cloud-based IIoT platform. Technicians can parameterise limit values in just a few seconds, without having to visit the measuring location. If the intelligent pressure sensor detects a drop in pressure to below the limit value, the instrument sends an alarm directly to the platform. The technician can view the status of the system and initiate the necessary maintenance measures.

Transformation of the maintenance strategy for district heating networks

The transformation from individual, manual data collection to intelligent metering points increases system visibility by more than a hundredfold, on average. With increased transparency, the focus shifts almost automatically from periodic monitoring to proactive maintenance. Network operators benefit not only from optimised resource utilisation, but also from improved system reliability.

Improve customer satisfaction through remote monitoring of end points

The operators of district heating networks are, thus, familiar with cases such as this: The phone rings and there’s a frustrated customer on the other end. The shower is cold. The fault must be rectified immediately. As the customer had not consumed any heat for hours, they did not realise that something was wrong with the system, despite the remote heat meter reading. Only when the service technician arrives at the customer’s premises can the troubleshooting begin. The reason for the failure is therefore only recognised on site – insufficient inlet pressure. Now it’s time to find the cause. After an elaborate and lengthy search, it is found – a defective pressure control valve.

Detection of an anomaly in the heat distribution.

With remote monitoring of the line pressure, such incidents can be avoided. Predictive monitoring via IIoT ensures that a fault is recognised no later than 30 minutes after it occurs. Alerting the responsible employee directly shortens the response time. The damage can be localised precisely in the online platform so that network operators can save many hours of troubleshooting and intervene at an early stage. This increases the reliability of the district heating network and thus the satisfaction of end customers.

Note

Thanks to IIoT, systems become transparent and can be monitored predictively and maintained more efficiently. On the WIKA website, you can find out more about IIoT solutions and instruments for district heating networks. There you can also read about WIKA’s comprehensive IIoT approach and how you can benefit from it. Should you have any further questions, your contact will gladly help you.

You can also read our blog posts

CO2 supply using IIoT for continuous dispensing

Using IIot in a vineyard optimises frost protection

mioty alliance drives wireless communication forward